Beckhoff «WT 850 GP» SYSTEM WICKET

RUSSIA and Central Asia

Automatic line for the production of bags with adhesive handles, model «WT 850 GP» SYSTEM WICKET

Description

All machine settings are set via the touch screen, BECKHOFF (Germany).

The machine has 10 standard servomotors, BECKHOFF (Germany).

The machine has a remote access system that allows you to configure and diagnose the machine directly from the manufacturer, without leaving specialists.

Technical parameters:

Max. the width of the film: 1600 mm

Burst length 300-750 mm

The width of the package 200-700 mm

Bottom seam 30-80 mm

Maximum diameter of the reinforcing tab 600 mm

The width of the roll of reinforcing tabs 140 mm

The length of the reinforcing tabs 100 mm

Thickness of the reinforcing tab 0.080-0.090 mm

Maximum performance with a cut-through handle 300 PCs / min

Maximum performance with a reinforced hole handle 250 PCs / min

Maximum line speed 80 m/min.

Film thickness

HDPE

LDPE

0.020-0.080 mm

0.040-0.080 mm

Total air consumption: 700 l / min

Total installed capacity: 40 kW

The main nodes:

• Servo motors: BECKHOFF(Germany);

• Operator panel: BECKHOFF(Germany);

• AC motors: ABB (Germany);

• Inverters: ABB (Germany);

• Gearboxes: NORD (Germany);

• Pneumatic equipment: FESTO (Germany);

• Contactless switches and photocells: SICK (Germany);

• Buttons: TELEMECANIQUE, (France);

• Contactors and automatic fuses: SCHNEIDER, France;Bearings:

• FAG from Germany and O. R. S. (Turkey)

Station roll-out:

• Folding device "Triangle»;

• Unwinding station with hydraulic device for lifting the roll from the floor;

• Control is performed by adjusting the AC motor;

• AC motor controlled by a guide with an ultrasonic sensor for web monitoring (machine diagnostics system via modem);

• Automatic tension control system;

• Photo-sensor device for monitoring the position of the unwinding roll, a device for laying the bottom seam; pneumatic Device for better fixing the sleeve; Max. diameter 1000mm;

• Handle production device;

The bookmark device of bottom seam.

The main device of the machine:

• Servo motors and servo drives from Beckhoff German stamps, in quantity - 9 PCs.

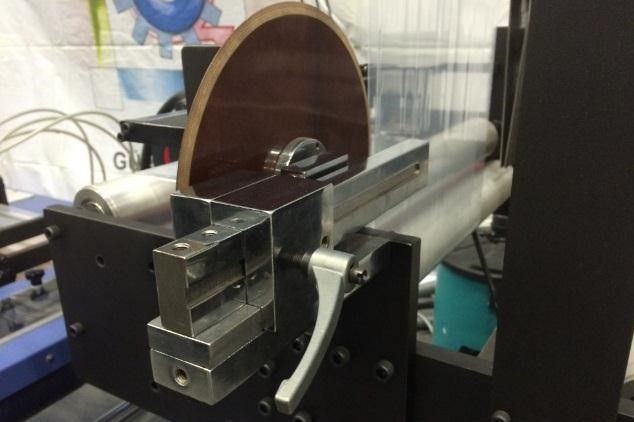

• Device for gluing handles.

• 8 rotating grippers.

• The device is the production of handles.

• Vacuum unit (fan system) for waste from for waste from the production of handles.

• Flipping knife for PE.

• Hydraulic lifting of the roll.

• Folding device.

• Edge position device with ultrasonic sensor.

• Bottom fold device.

• Pre-sealing unit.

• Photocell for a printed package.

"Wicketer" device and pipeline:

• 3 lines and 8 blades are controlled by a servo motor;

• The stowage system and conveyor are controlled by a servo motor;

• 4 working laying stations;

• Vacuum device of blades for holding packages when feeding to the conveyor, 7.5 kW;

• SIMCO static removal system»,

• Protective screens to avoid industrial injuries to workers.

The cost of equipment on the terms of pickup, Rostov-on-don 309000 USD, excluding options including VAT 20%

Payment term:

30% prepayment

70% prepayment before shipment from the warehouse

Setup and training: 2 days, free of charge. (The buyer pays only for travel and accommodation of the Seller's specialists).

The warranty period is 1 year., from the moment the equipment is put into operation

Delivery time of equipment in stock in Rostov on don