2 Strema COTTON SWABS MACHINE

Ref :

2604607-4-MT

Condition :

Used

Manufacturer :

Strema

Model :

COTTON SWABS MACHINE

Year(s) :

2000

Quantity :

2

Location :

Seller or machines location:

EUROPE (Western and Northern)

EUROPE (Western and Northern)

Last check :

29 Sep. 2024

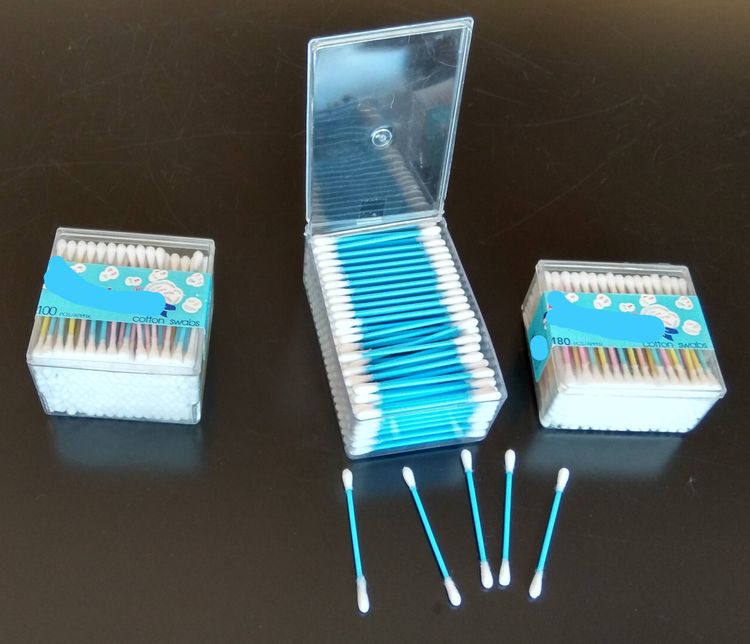

2 STREMA (NYCORA) MACHINES FOR COTTON SWABS

STANDARD SWABS

SAFETY -BABY SWABS

OLIVE SHAPE BUDS

IN ROUND OR RECTANGULAR OR IN SQUARE PLASTIC BOXES

PRODUCTION 1200 SWABS PER MINUTE

VERY SIMPLE SETTINGS AND MAINTENANCE

IN VERY GOOD WORKING CONDITION

LOW MAINTENANCE -COMMON SPARE PARTS FROM MARKET

IMMEDIATELY AVAILABLE

Other machines similar to 2 Strema COTTON SWABS MACHINE

1

Leomat Rotocontrol P440D

Location :

EUROPE (Western and Northern)

Year(s) :

2015

1

ABG OMEGA 330 Converter

Location :

EUROPE (Western and Northern)

Year(s) :

2007

1

Nilpeter FA 4250

Location :

EUROPE (Western and Northern)

Year(s) :

2007