Comer complete MG Paper machine for bags and packaging grades 2.450 mm at pope min.60 gsm- Average 80-180 gsm Avg 80 TP- Max 100 TPD

EUROPE (Western and Northern)

Complete Paper Production Plant for MG paper for bags and packaging grades, max speed: 400 mpm,

-Complete with Stock Preparation, Rewinder, Sheet-Cutter, Boiler, Vacuum plant and Flotator for water treatment and fiber recovery.

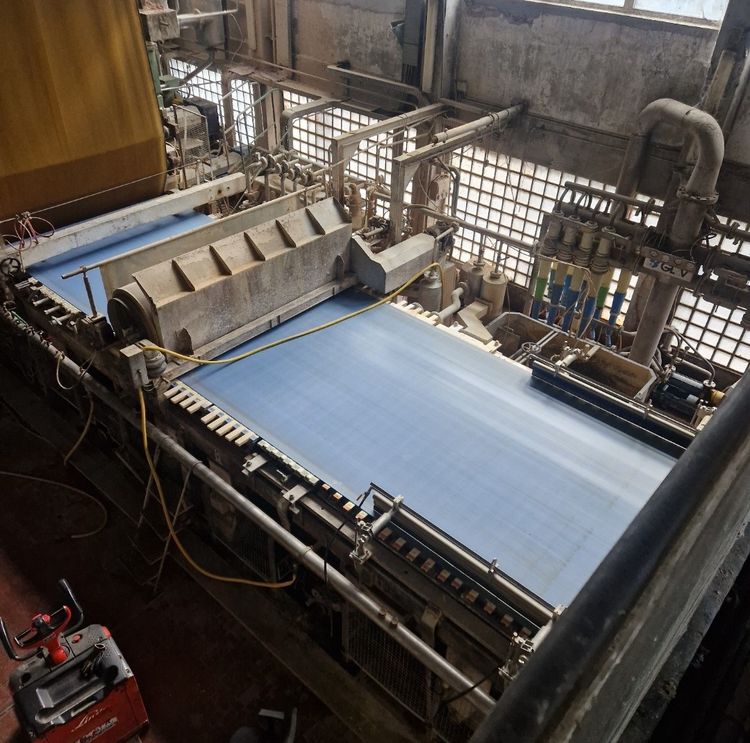

Comer fully automatic Headbox 18.000 lpm, pc controlled for profile control, with very recent profile controls Tasowheel

Fourdrinier 10 m long with Dandy Roll

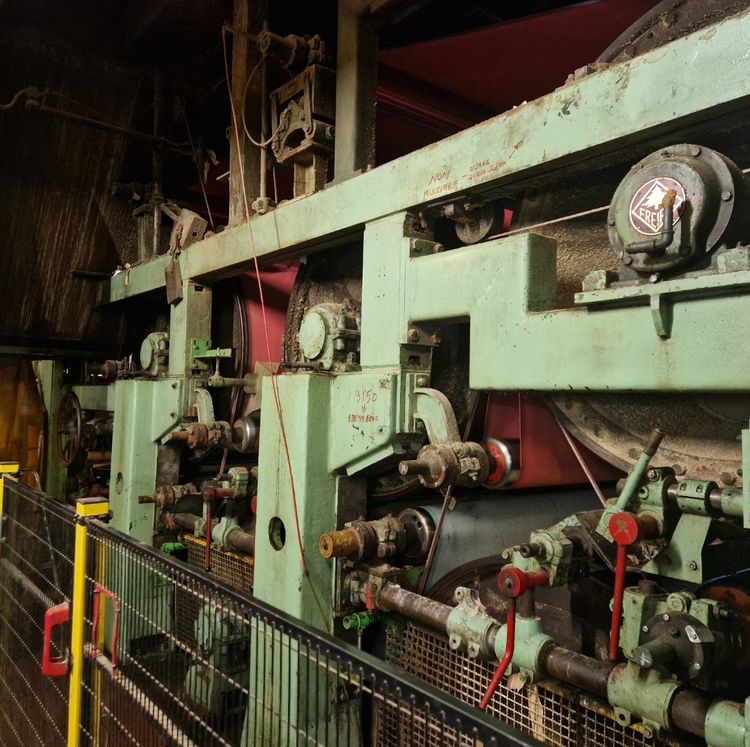

Tri-nip Press as follows:

First Press installed in 2001, maker Freiria, modified by Maule with pick up roll, second nip on the same central press

Second press with granite roll

Dryers before Yankee: 9 dryers 3 bar with automatic gradual drying controlled by pc

Yankee cylinder with air high yeld hood 330° C with Aerothermic burner, 2800 mm wide, diam. 3500 mm, made by Escher Wyss, 3 bar, hard metal covered by Voith in 2010

Dryers after Yankee: 6 dryers recently installed, maker: Overmade, 5 bar

N. 2 x cooling rolls (one for each side of the paper)

Machine calender with upper Kuster cylinder and lower cast iron cylinder

Anti-curling system

QCS by Scienta installed in 2009 for control of grammage, moisture, thickness

Pope Reeler

- Spares as available (most rolls, 2 spares of the granite roll)