Continuous laminating

AMERICA North (USA-Canada-Mexico)

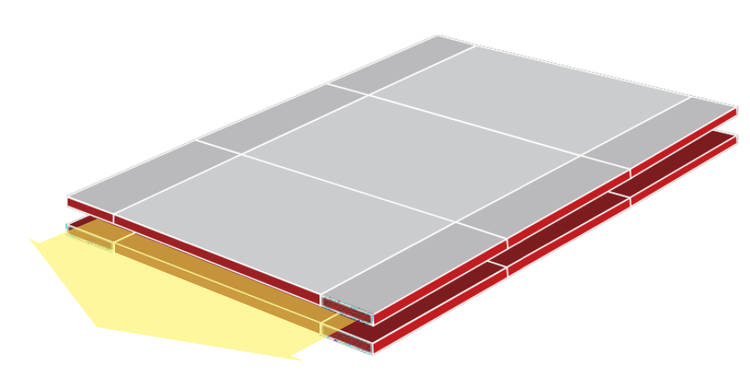

OUR CONTINUOUS PRODUCTION LINE OF COMPOSITE MATERIALS CAN WORK CONTINUOUSLY, WITH INTEGRATED CONTACT HEATING AND CONTACT COOLING DOUBLE BELT PRESS. IT GENTLY HEAT THE MATERIAL TO BE LAMINATED TO ACHIEVE OPTIMAL BONDING WITH STRONG BONDING STRENGTH OVER ALL LENGTHS OF THE HEATING ZONE. AFTER HEATING THE MATERIAL, PRESS IT TIGHTLY THROUGH THE PRESSURE ROLLER, AND CALIBRATE IT TO THE DEFINED THICKNESS ACCORDING TO THE REQUIREMENTS. THE COOLING PROCESS INSIDE THE MACHINE CAN ACHIEVE HIGHER STABILITY. DUE TO THE HIGH-PRECISION WORKFLOW, IT CAN BE LAMINATED VERY SMOOTHLY.

THE PRESSURE IS TRANSMITTED THROUGH THE UPPER AND LOWER CONVEYOR BELTS AND THE CONTACT HEATING AND COOLING SYSTEMS ARE INTEGRATED. THE MATERIAL IS EVENLY HEATED. DUE TO THE LONG ENOUGH HEATING ZONE, THE MATERIAL WILL BE PERFECTLY COMPOSITE AND HAVE HIGH STRENGTH.THE MATERIAL BECOMES VERY STRONG AFTER HEATING. THE GAP AND HEIGHT BETWEEN THE CONVEYOR BELTS CAN BE ACCURATELY ADJUSTED BY ADJUSTING THE MATERIAL HEIGHT THROUGH THE PRESSURE ROLLER. TO ENSURE THE COMPOSITE STRENGTH, THE MATERIAL IS COOLED BEFORE LEAVING THE CONVEYOR BELT.

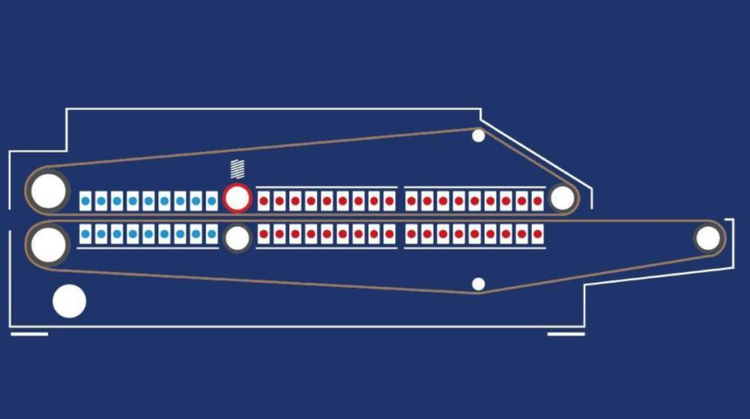

DISTRIBUTION OF HEATING ZONES:

HAVE 18 HEATING ZONES, 9 ZONES IN THE TOP HEATING SYSTEM, AND 9 ZONES IN THE BOTTOM HEATING SYSTEM. 18 HEATING ZONES ARE INDEPENDENTLY CONTROLLED, AND EACH ZONE CAN BE INDIVIDUALLY HEATED ACCORDING TO PROCESS REQUIREMENTS.

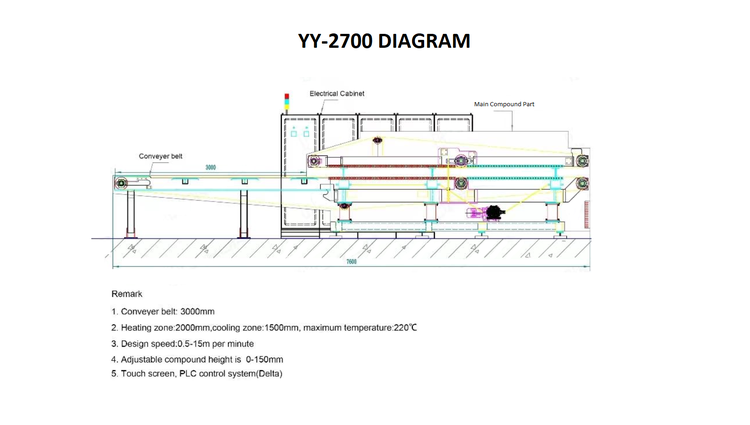

HOST PARAMETERS:

DESCRIPTION OF DOUBLE BELT CONTINUOUS LAMINATING COMPOUND MACHINE

EFFECTIVE DOOR WIDTH: 1800mm;

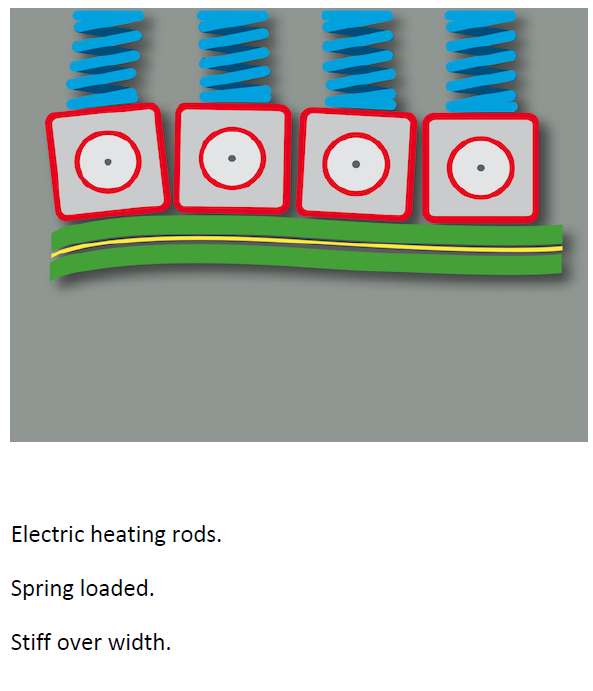

HEATING FORM: ELECTRIC HEATING;

LENGTH OF HEATING ZONE: 2000mm;

LENGTH OF COOLING ZONE: 1500mm;

GAP HEIGHT: 0/150mm;

CONVEYOR BELT FORM: ELECTRIC HEATING ANTI-STATIC TEFLON TAPE (WITH CONNECTOR);

CONVEYOR BELT THICKNESS: 0.5mm;

HEATING POWER: 145KW;

TOTAL POWER OF EQUIPMENT: 160KW(NOT INCLUDE CHILLER);

DESIGN SPEED: 0.5-10 M / MIN;

CONTROL SYSTEM: DELTA;

TRANSFER MOTOR: SERVO MOTOR;

DEVICE COLOR: DESIGNATED BY THE SELLER.

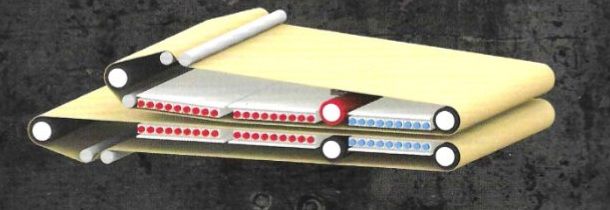

THE STRUCTURE PRINCIPLE OF THIS MACHINE IS TO TRANSFER PRESSURE THROUGH TWO TEFLON BELTS AND INTEGRATE THE CONTACT HEATING AND COOLING SYSTEM. THE COMPOSITE MATERIALS WILL BE UNIFORMLY HEATED, AND THE MATERIALS WILL BE PERFECTLY COMPOUNDED WITH HIGH STRENGTH. AFTER HEATING, THE MATERIALS CAN BE COMPOUNDED TOGETHER. ADJUST THE HEIGHT OF THE MATERIALS THROUGH THE PRESSURE ROLLER. IN ORDER TO ENSURE THE COMPOSITE STRENGTH, THE MATERIALS WILL BE COOLED BEFORE LEAVING THE CONVEYOR BELT.

COMPOUND DEVICE: UPPER AND LOWER CONVEYOR BELT, HEATING DEVICE, COOLING DEVICE, CONVEYOR BELT GAP ADJUSTMENT DEVICE, PRESSURE ROLLER CONSTANT PRESSURE DEVICE.

CONVEYING FLAT BELT: ANTI-STATIC TEFLON BELT. THE PERIPHERY OF THE FLAT BELT IS PULLED BY THE TENSION SPRING, AND THE POWER IS DRIVEN BY THE CHAIN. THE FLAT BELT IS SYNCHRONOUSLY DRIVEN BY THE MOTOR THROUGH THE ACTIVE AND PASSIVE RUBBER ROLLERS AND THE CHAIN.

HEATING DEVICE: THE UPPER AND LOWER SPECIAL HEATING PLATES ARE USED FOR DISTRIBUTED HEATING TO EVENLY HEAT THE TEFLON FLAT BELT TO ENSURE THE BALANCE OF LEFT AND RIGHT TEMPERATURE DIFFERENCES. THE UPPER AND LOWER HEATING PLATES ARE INDEPENDENTLY CONTROLLED AND DISPLAYED BY NINE GROUPS OF TEMPERATURE CONTROLLERS. ENSURE THE HEATING TEMPERATURE.

COOLING DEVICE: THE ALUMINUM PLATE IS SYMMETRICALLY DISTRIBUTED FROM TOP TO BOTTOM, AND THE FLAT STRIP IS EVENLY COOLED. THE ALUMINUM PLATE IS FED WITH COOLING WATER AND CIRCULATED THROUGH THE COOLING UNIT TOENSURE THE COOLING TEMPERATURE. ENSURE UNIFORM COOLING AND NO DEFORMATION.

FLAT BELT GAP ADJUSTMENT DEVICE: THE ELEVATORS ON BOTH SIDES ARE CONTROLLED BY THE MOTOR, THE ENCODER MEASURES AND FEEDS BACK, AND THE GAP IS CONTROLLED BY THE PROGRAM.

GAP ADJUSTMENT DEVICE OF PRESS ROLL: THE ENCODER MEASURES AND FEEDS BACK, AND THE GAP IS CONTROLLED BY PROGRAM.

PRESSURE ROLLER CONSTANT PRESSURE DEVICE: THE PNEUMATIC PRESSURE OF UPPER AND LOWER ROLLERS CAN BE ADJUSTED THROUGH AIR CYLINDER, PRESSURE SENSOR AND REGULATING VALVE, AND THE PRESSURE CAN BE ADJUSTED ON THE TOUCH SCREEN.

OTHER UNITS

ELECTRICAL CONTROL SYSTEM

THE ELECTRICAL MACHINE CONTROL IS BASED ON A DELTA AUTOMATION SYSTEM, INCLUDE PLC, CONTROL INSTRUMENTS AND MOTOR CONTROLLING.

THE OPERATION IS CONTROLLED BY TOUCH PANELS OR VIA PC.