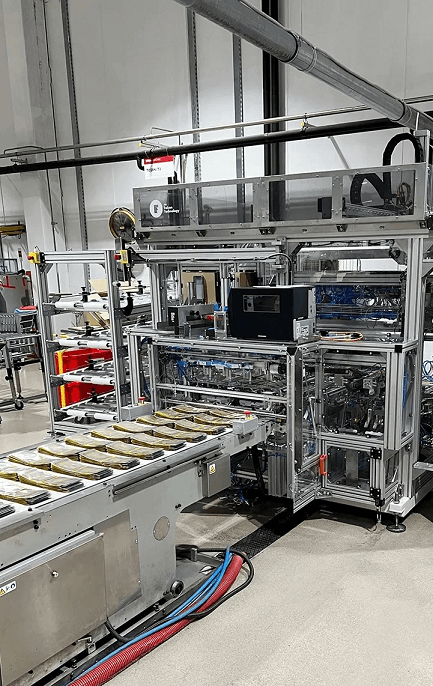

Falcon Nostromo "End-of-Line Pouch Packing Machine (Pre-made Bags) 95x140 mm

EUROPE (Western and Northern)

Falcon Nostromo

Custom-Made Pouch Packing Machine

1. General Description

The Nostromo is a custom-engineered, fully automated pouch packing system designed

for high-speed, multi-line production with full traceability and minimal operator intervention.

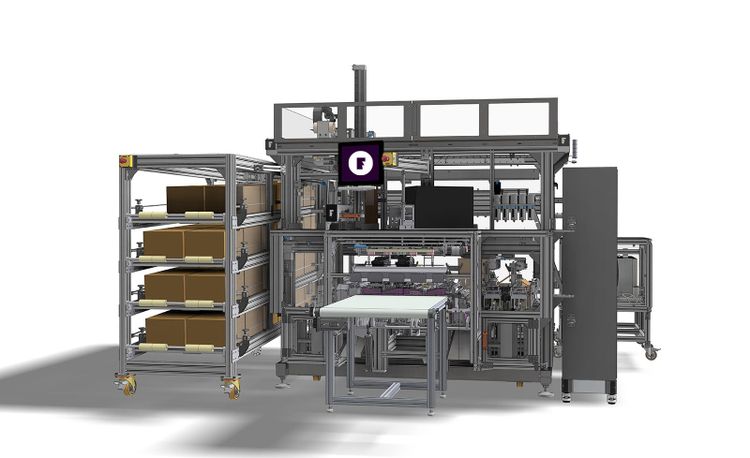

It is built as a modular platform consisting of three integrated units:

1. Main Module – Core pouch handling, quality control, and communication unit

2. Box Forming Module – Automatic forming and preparation of boxes

3. Box Collector Module – Final box handling and palletizing unit

The modular design allows flexible configuration and scalability for different production

environments. The Main Module is easily movable and can be re-deployed across multiple

converter or packing lines within the facility.

The module’s mobility system and quick-connect interfaces are designed so that a single

operator can safely and independently perform relocation and setup without the need for

technical support or additional lifting equipment. This ensures maximum flexibility and utilization

of the Nostromo system across production lines.

2. System Configuration and Modules

2.1 Main Module

● Function: Core pouch packing, inspection, and traceability operations

● Dimensions:

○ Length: 3200 mm

○ Width: 2340 mm

○ Height: 2250 mm

● Features:

○ Supports up to 4 pouch lines simultaneously

○ Throughput: Up to 250 cpm

○ Autonomous operation: Up to 4 hours without operator intervention

○ Mobility:

■ Mounted on industrial casters and leveling feet - possible upgrade to

an automated screw jack system

■ Designed for quick disconnection and reinstallation

■ Enables use on multiple production lines

○ Integrated Functions:

■ Sampling and date printing on selected pouches

■ Rejected pouch storage and tracking

■ Box labeling

○ Full traceability through integrated data acquisition system

2.2 Box Forming Module

● Function: Automated folding, forming, and preparation of boxes

● Integration: Interfaces directly with the main module for synchronized operation

2.3 Box Collector Module

● Function: Final collection, stacking, and palletizing of filled boxes

● Box Handling Options:

○ Shelving System – Automated rack stacking

○ Direct Palletizing (Custom Manipulator) – In-house designed manipulator

system

○ Direct Palletizing (Robotic Arm) – Integration with an industrial robotic arm

● Features:

○ Automatic labeling and sorting

3. Performance and Capabilities

● Throughput: Up to 250 pouches/minute

● Autonomous Operation: Up to 4 hours continuous run

● Simultaneous Lines: 4 pouch lines

● Quality Control: Inline sampling, date printing, and rejection

4. Connectivity and Integration

● Upstream Connection: Real-time synchronization with TOTANI converter machine

● ERP Integration: Bidirectional communication for batch tracking and reporting

● Control System: Centralized PLC and HMI with unified operation interface

5. Inspection and Testing

5.1 Factory Acceptance Test (FAT)

Includes verification of:

● System throughput performance

● Fault detection functionality

● Rejection accuracy and logging

5.2 Integration Testing

● End-to-end communication and synchronization with TOTANI converter machine

● ERP data exchange and traceability verification

6. Documentation and Support

● Complete set of mechanical and electrical drawings

● Detailed operation and maintenance manuals

● Comprehensive spare parts list

7. Packing and Transportation

● Machine shipped in modular sections with protective packaging

● Designed for safe handling and transport using standard freight methods

● Modules are clearly labeled and prepared for quick on-site installation

8. Safety and Compliance

● Conforms to CE and ISO 12100 standards

● Equipped with emergency stops, safety switches and protective guarding

9. Utilities and Power Requirements

● Electrical Supply: 400V, 50 Hz , 25 A

● Compressed Air: 6 bar (dry and filtered)

● Power Consumption: To be defined per configuration

10. Maintenance and Service

● Remote monitoring and support (optional)

● Recommended preventive maintenance schedule provided