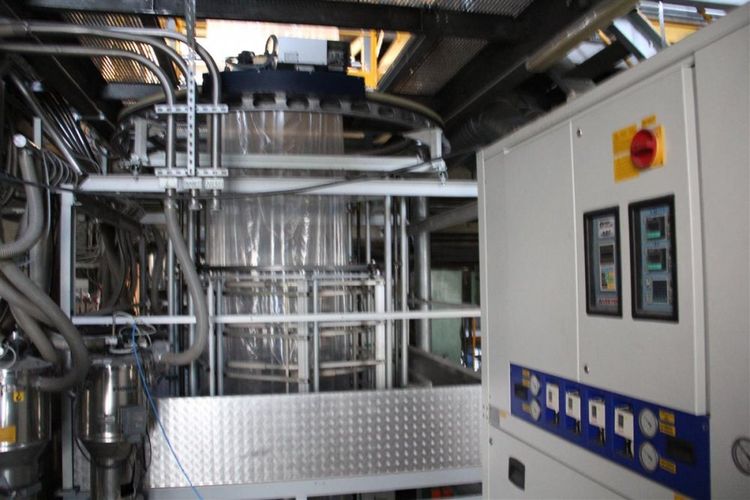

Kiefel Kiron ( Coex ) Film Blowing Machine

EUROPE (Western and Northern)

Number of layers 3

Film structure ABC

Material LDPE, LLDPE, MDPE

Film Width (mm) 2200

Output (Kg/h) 600 depending on material

Extruder 1 Layer ref: A

Screw diam 70mm

26L/D .Gravimetric dosing unit 5 components. Motor AC 75Kw. Hydraulic screen changer

Extruder 2 Layer ref: B

Screw diam 100mm

26L/D.Gravimetric dosing unit 4 components. Motor AC 145Kw. Hydraulic screen changer

Extruder 3 Layer ref: C

Screw diam 70mm

26L/D.Gravimetric dosing unit 5 components. Motor AC 75Kw. Hydraulic screen changer

Head Kirion 250/500-3 suitable for die diam 250-500mm . Cool ring Perfect cool . IBC

Die diam (mm) 400mm and 500mm

Thickness controll system Yes automatic Profile Control C2

Bubble cage Additional ultrasonic bubble control N2200-C including ultrasonic web detector. Motorized adjustment

Take off unit Rotating T2200, Zero Touch 2200 air cushion

Corona treatment Double side

Web guide Yes

Rewinder max reel diameter 1200

Rewinder

Kirion W 2200 M2 Center and surface driven.

Possibility of gap and contact winding. tension 40-400N.

Mechanical speed 200M/min.

S wrap cooling unit.

Automatic reels extraction and new shaft loading system

Additional information

Edge trim system.

Inline slitting system Twin chiller for Kirion C

In a blown film extruder PE granulates (or other polymer) are melted in an extruder

and pushed through a circular die extruding a tube of molten polymer.

Tube is then inflated to multiples of its initial diameter and cooled to form a thin film.

Bobble is later collapsed and re-winded.