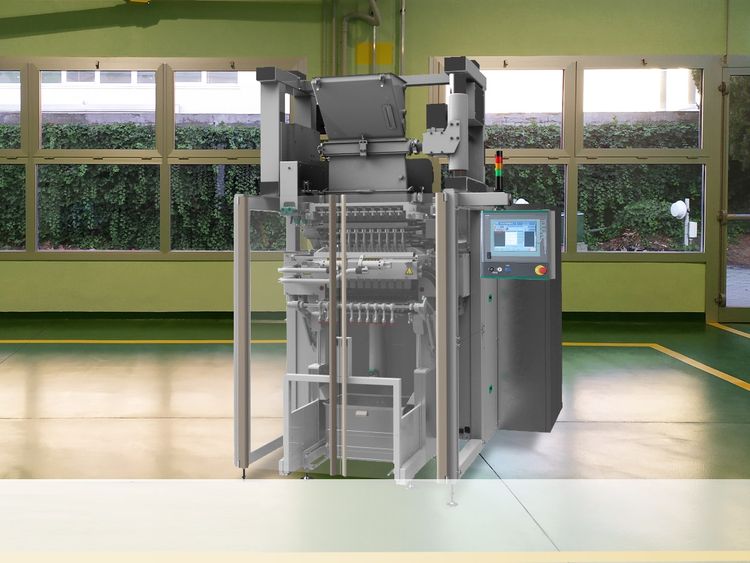

MARCHESINI Schmucker MSP560, Vertical multilane stick pack machine

EUROPE (Western and Northern)

Machine basement built with sturdy anodized aluminium plates.

The working area is a balcony type layout,

separated from the mechanical movements by means of

aluminium plates covered by stainless steel sheet.

All drives are enclosed in the machine internal structure

and so there are no motors visible in the working area.

Easy access to the parts in contact with the product for service and cleaning purposes.

In the design, GMP norms have been strictly followed and the machines is delivered with the CE mark.

Machine control and all operator interface display functions are

achieved by an industrial PC Siemens placed

on machine right side on a swivelling arm.

On this machine all size change operations are

accessible from the outside. For size changeover,

the operator has just to accomplish the following operations:

to recall an existing size,

previously set and saved

to introduce a new size,

due to different sachet length only

and different stacking number in case of connection to a conveyor.

Stacking number control is one of the control functions

of the Stick pack machine.

to position transversal cutting tools

(stick pack length) by means of a hand wheel

with digital indicator to reach a new cut position.

The position of cutting tools for longitudinal cut (stick pack width)

is adjustable with a contrast roller equipped with a graduated scale.

A hand wheel is available to adjust contrast roller only,

without affecting cutting tool position.

All main machine drives, from film pulling to stick pack discharge,

are controlled by servo motors (Parker) or pneumatic actuators.

Operations that do not require any changes

such as vertical and horizontal sealing are of pneumatic type,

thus making size changeover very easy.

Instead of classic pulling with transversal sealing tools,

a special group to pull stick pack is applied,

which makes all machine working area more accessible.