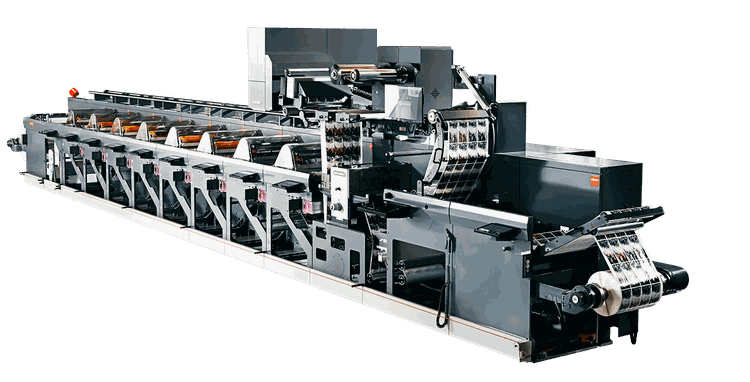

Nilpeter FA4 6 410 mm

EUROPE (Western and Northern)

6-color - like new

Printing Technology: Modular, servo-driven flexographic press

Web width (max): 420 mm / 16½″

Printing width (max): 410 mm

Mechanical speed: 0 – 175 m/min

Applications: Self-adhesive labels, films, flexible packaging substrates

Substrate range: 100–220 μm (standard), extendable up to 350 μm with carton kit

Machine Configuration & Features:

Unwind Section

Servo-driven unwind

Automatic web guiding

Pneumatic splice table

40″ roll lift with double-arm system (max. 350 kg)

Prepared for corona treater and web cleaning system

Printing Units :

CLEANINKING Flexo Modules

6 servo-driven flexo units (quick-change design)

CLEANINKING cassette system for fast ink/plate change

Servo-driven anilox system

Easy-load sleeve mandrels

Fully automatic 360° register control

Pre-setting of impression & register

Drying & Curing

Hot-air drying system (extended footprint)

UV-lamps (GEW E2C) integrated with exhaust system

Prepared for additional UV stations & hot-air drying

Converting & Finishing Section:

• Rotary die station, servo-driven, 12"–25" repeat

• Option for dual rotary die-cutting

• Flatbed die-cutting preparation

• Matrix stripping tower

• Infeed & outfeed nip systems

• Lamination tower (cold foil & lamination capability)

• Turn-bar and de/relamination options