30 TPD SUNFLOWER EDIBLE OIL

Ref :

2591413-7-MT

Condition :

Used

Manufacturer :

-

Model :

30 TPD SUNFLOWER EDIBLE OIL

Year(s) :

2007

Quantity :

1

Location :

Seller or machines location:

EUROPE (Western and Northern)

EUROPE (Western and Northern)

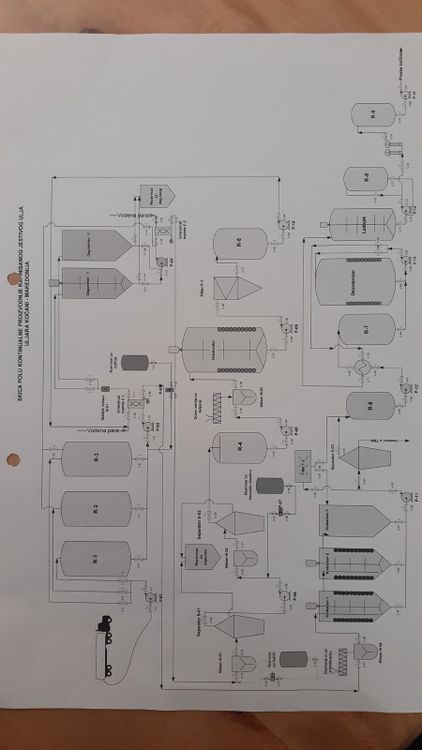

30 TPD SUNFLOWER EDIBLE OIL MINI-REFINERY + FILLING LINE

RECEIPT OF CRUDE OIL

DEGUMMING OF CRUDE OIL

WINTERIZATION OF CRUDE OIL

NEUTRALIZATION

OIL WASHING

OIL DRYING

OIL BLEACHING

DEODORIZATION

OIL COOLING

FILLING

Other machines similar to 30 TPD SUNFLOWER EDIBLE OIL

1

Vegetable blanching line PKC

Location :

EUROPE (Central and Eastern)

1

Bruynooghe RK131421 roller sorting machine

Location :

EUROPE (Western and Northern)

Year(s) :

2003

1

Greefa CombiSort apple & fruit sorting machine

Location :

EUROPE (Western and Northern)

Year(s) :

2023

1

Barrel Washer TONG DESTONING LINE

Location :

EUROPE (Western and Northern)

Year(s) :

2017