Others Vítkovice Steam Boiler 40 t/h

EUROPE (Central and Eastern)

used Steam Boiler with turbine, rated thermal power / steam: 38 MW / 40 t/h

1. BOILER

1.1 GENERAL INFORMATION

Manufacturer: Vitkovice Inc. Ostrava Type: DENAPAK licensed CMI, 1994

In operation since: 1996

Calorific heat exchange area of 1142 m2

The cooling medium: steam

The pressure and temperature of steam: 6,5 MP / 490°C

Rated feedwater temperature: according fuels

Rated thermal power / steam: 38 MW / 40 t/h

Fuel type: ZP, TO

Dimensions: 10 x 19 x 14 m

Total weight: 125,000 kg

Burner: number 1

Manufacturer: SAACKE GmbH

Type: DD ZG 14

Serial number 9402/012

Flue chimney: into a steel chimney diameter 1400 mm

1.2 COMPONENT OF THE BOILER

1.2.1 INTRODUCTION

Main parts of the boiler DENAPAK:

Pressurized combustion chamber and the convection part.

The boiler consists of upper and lower drum to which are connected the plurality of tubes

forming a right, left, back and front wall, which together form the casing of the boiler.

Another part of the boiler tube walls are composed of:

- Combustion chamber in which heat is transferred mainly by radiation

- Convection part, in which heat is transferred mainly by radiation

Gas-tight welded and cold perimeter walls with insulation and sheeting.

The burner is on the front wall of the combustion chamber.

The combustion chamber is provided with peepholes. Individual parts of the boiler are made available to hatch.

1.1.2 DESCRIPTION BOILERS

The boiler consists of:

a) 1 steam drum consisting of two dished a cylindrical section 1190 mm, length 9500 mm, wall thickness 70 mm, wall thickness of the bottom 40 mm.

The drum is provided with a manhole. Inside there is an internals and steam separator.

b) one water-drum consisting of two arched and cylindrical section 740 mm, length 9500 mm, wall thickness 40 mm, wall thickness of the bottom 30 mm.

The drum is provided with a manhole inside the drum feedwater heaters from Tr ø 51 / 3.6.

c) steam drum is provided specific level indication chamber outer diameter 219 mm, to which are attached 2 straight with level and 3 level monitor connected to the M + R boiler.

d) one convection tube bundle evaporator of Tr ø 51 / 3.6.

e) 1 convection tube bundle evaporator (input-protection) from the Tr ø 51 / 3.6.

f) 1 rear wall of the drum Tr ø 51 / 3.6.

g) 1 diaphragm walls of Tr ø 57/5 D-shaped, which forms the combustion chamber.

h) one left side wall of the combustion chamber of Tr ø 51 / 4.5

i) one front and one rear wall of Tr ø 57/5. Both walls at the bottom of the mouth of the chambers Tr ø168 / 20.

These chambers are connected with a water drum Tr ø 57/5.

j) 1 left outer side wall of the boiler Tr ø 57/5

k) 8 downpipes ø 114.3 / 4.5. Pipes are 4 pieces located outside the flue gas stream at both ends of the cylindrical part of the drum.

l) 20 outlet steam pipes ø 57/5. These pipes to a collecting chamber steam Tr ø 219/16 welded and into the steam drum rolling. The bottom of the steam chamber are ø 219/38.

m) superheater 1 consists of coils Tr 33.7 / 4, an inlet chamber Tr ø 219/16, the bottom ø 219/33, the outlet chamber Tr 219 / 12.5, the bottom ø 219/33.

n) superheater consists of two coils Tr 33.7 / 5, an inlet chamber Tr 219 / 12.5, the bottom ø 219/33, the outlet chamber Tr ø 219/16, the bottom ø 219/33.

1.2.3 SECURITY DEVICES

2 management of insurance valves superheater

2 level meter with direct pointing

3 level monitor connected to the M + R boilers

1 pressure gauge with valve and test connection

1 pressure switch

2. ECONOMISER

2.1. GENERAL INFORMATION

Manufacturer: VÍTKOVICE Inc.

Y.o.v. 1994

Type: inseparable, detached horizontal eco licensed CMI

Design pressure: 7.7 MPa

Working temperature:

Fuel:

1 / Natural Gas

- Flue - Input / Output: 434 ° C / 163 ° C

- Water inlet / outlet: 105 ° C / 200 ° C

2 / oil

- Flue gas inlet / outlet: 426 ° C / 185 ° C

- Water inlet / outlet: 135 ° C / 214 ° C

Water flow rate: 40-44 t / h

Water content: 3.6 m3

Heating surface: 552 m3

2.2. COMPONENT

- Coils are arranged horizontally in blocks

- Forced Flow

PART OF EKA

Input, output chamber, two bottom coils, cabinet

3. CHIMNEY

4. Air ducts

1 / sucking channel - 1200 x 800 mm

2 / blowers - radial RVM - 1250-5NP 0 with control mechanism in the intake with electric engine 1 AF 315 SK 4, 132 kW, 1484 r/min, 380 V

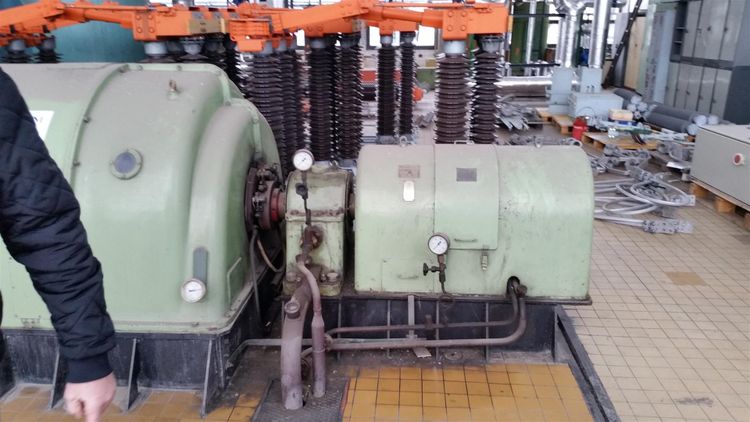

5. TURBINE

Manufacturer: Skoda/Siemens

Type: PR4/4-3,7/1/0,4

Rated power of the alternator terminals at cos 0.8: 4 MW

Turbine speed: 3000 min-1

Rated steam pressure to quickly shut the valve: 3,7 MPa (37,74 kp.cm-2)

Nominal temperature steam for quick shut-off valve: 400°C

Nominal backpressure: 0,4 Mpa (4,08 kp.cm-2)

Nominal backpressure: 0,4 Mpa (4,08 kp.cm-2)

Lower and upper limit backpressure: 0,3 - 0,5 Mpa (3,06 - 5,1 kp.cm-2)

The boiler and turbine will be the modernization and on the plate will be the year 94/2016.

Both devices can be operated separately or together, depending on the technological needs.