Taiwan Brand 1.520 mm Toilet paper production line

MIDDLE EAST

Production Area: Toilet paper, paper towels, garage rolls, and examination tablecloths

Reel Width: 152 cm

Product Winding Diameter: Up to Ø500 mm

Main Motor Power: 11 kW

Operating Speed: 250 m/min

see photos and video: https://www.youtube.com/watch?v=3N9hd3BLSjM

Lamination: Suitable for winding with and without lamination

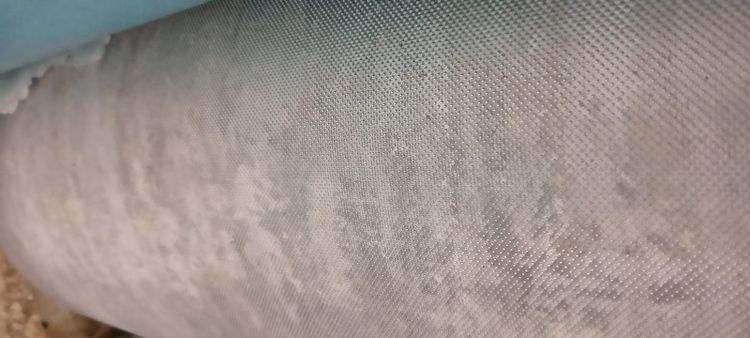

Embossing System:

Top embossing: Standard micro pattern

Bottom embossing: 3 options – cloud pattern, micro cloud pattern, and micro pattern

Edge embossing (embossing) available

(Embossing printing deco rubber roller and mating roller spares available)

Reeling Unit: 2

Production can be done with two-ply reels or two separate single-ply reels

Perforation Unit:

Servo-driven system

2-knife rotary structure

Cutting length can be adjusted mechanically or digitally up to 15 Adjustable from cm to 70 cm

Automation Features:

Automatic bobbin feeding

Automatic end cutting and end glue application

Automatic sealing

Digital Control Panel:

Measurement tracking

Perforation length and log quantity displayed

Lamination timing

Perforation open/close control

Send feedback

End glue application timing

Embossing Pressure Adjustment: Adjustable with air pressure

Winding System:

Automatic axis fixing system for log wrapping

Provides smooth winding without warping

Comes with equipment suitable for Ø50 mm and Ø60 mm diameter axis pipes

Safety Equipment:

(Protection walls and protective covers have been newly added.)