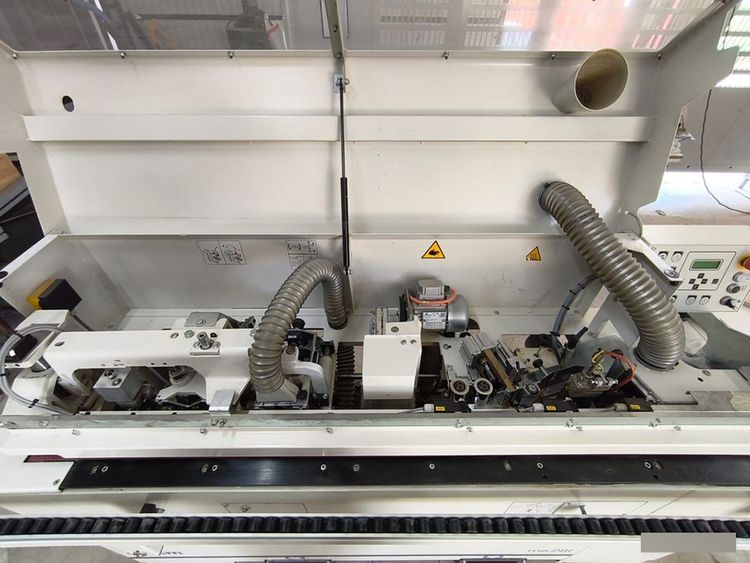

SCM ME28 T

EUROPE (Western and Northern)

. SCM ME28 T edgebander, Very good condition — Year: 2020.

. Complies with European standards.

. Equipped with a grinding unit with an 80 mm diameter diamond tool, extraction hoods,

and an air cushion device for optimal panel cleaning and linearity during pre-machining.

. 4 wood grips available on the grinder: 0.5 / 1 / 1.5 / 2 mm — vertically movable tool (also useful during sharpening).

. Hot-melt glue pot unit with rapid heating (Teflon), internal resistance glue roller,

integrated PLC temperature control, and automatic unused glue recovery device.

. Automatic feeder for roll edges with a cutter (thin edges up to 3 mm) — rotating roll holder Ø 730 mm.

. Motorized end trimming unit for 90° trimming of the front/rear excess edge (blade depth adjustable and memorized by digital indicator).

. Overlapping trimming unit (Ø 72 mm cutters) for radiused edges (2 mm — 3 mm on request)

and wood edges up to 5 mm; horizontal and vertical copiers for perfect alignment.

. Edge scraping unit for finishing 2 mm PVC/ABS edges (3 mm on request) — high-rigidity structure, chrome-plated front/vertical copiers, knife set included (R = 2 mm; R = 3 mm on request) — manual exclusion option.

. Glue scraping unit to remove excess glue and improve panel cleaning.

. Not suitable for machining Formica edges.

TECHNICAL DATA:

. Condition: Very good condition — 1st hand repair.

. Edge compatibility: up to 5 mm for wood edges (flush trimming), 2 mm PVC/ABS edges (3 mm on request), trimmers for thin edges up to 3 mm.

. Flush trimming cutter diameter: 72 mm.

. Diamond tool diameter (grinder): 80 mm.

. Grinder grip settings: 0.5 / 1 / 1.5 / 2 mm (4 positions).

. Roll holder diameter: 730 mm.

. Glue temperature control: integrated PLC + standby mode (automatic temperature reduction).

. Roll feeder: automatic with cutter.

. Vacuum and air cushion devices for cleaning.

. Digital indicators for adjustments/memorization of dimensions.

. Recent replacements: calibration tool holder and drive belt replaced at the end of 2024.

OPTIONS:

. Special end-cutting unit with "rounding" function (replacing the standard unit) — smooths corners by beveling; on solid edges, the cut remains straight.

. "Rounding" option equipment: 1 high-frequency motor 0.37 kW – 12,000 rpm; 1 blade Ø 90 mm Z10.

. Panel preheating device (positioned before the gluing unit) to improve glue adhesion (useful in cold environments or for stored panels).

ADDITIONAL INFORMATION:

. Calibration tool holder and drive belt replaced: end of 2024.

. First-hand trade-in.