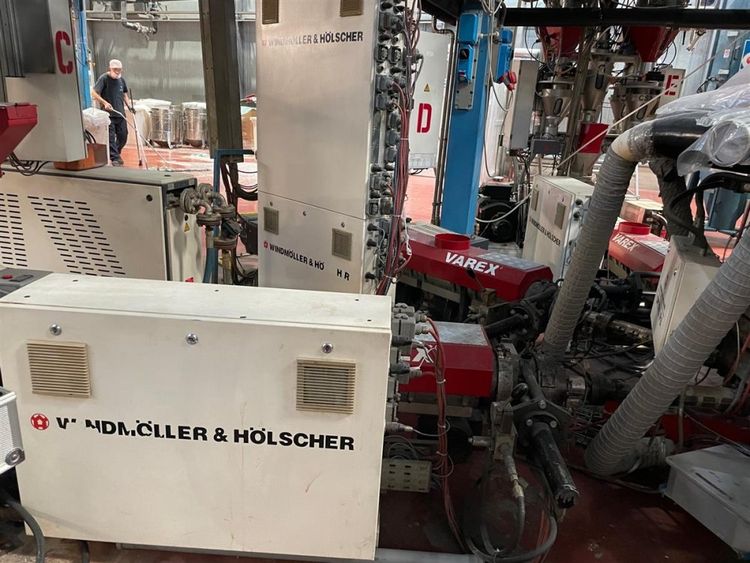

Windmoller & Holscher Varex 5 layers Blown film extrusion line

EUROPE (Western and Northern)

Number of layers 5

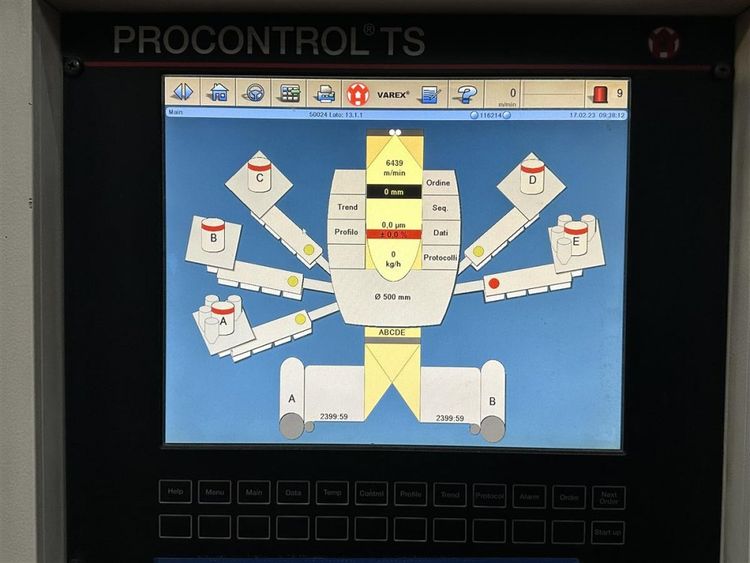

Overhaul/renovation HMI, supervision and some inverters upgraded in 2019

Film structure ABCDE

Material Barrier and lamination film, LDPE films

Film Width 2100

Extruder 1 Layer ref: A

Screw diam 70mm

motor 89Kw, gravimetric doser 5 comp

Extruder 2 Layer ref: B

Screw diam 50mm

motor 29Kw gravimetric doser 1 comp

Extruder 3 Layer ref: C

Screw diam 60mm

motor 89Kw gravimetric doser 3 comp

Extruder 4 Layer ref: D

Screw diam 50mm

motor 29Kw gravimetric doser 1 comp

Extruder 5 Layer ref: E

Screw diam 70mm

motor 89Kw gravimetric doser 5 comp

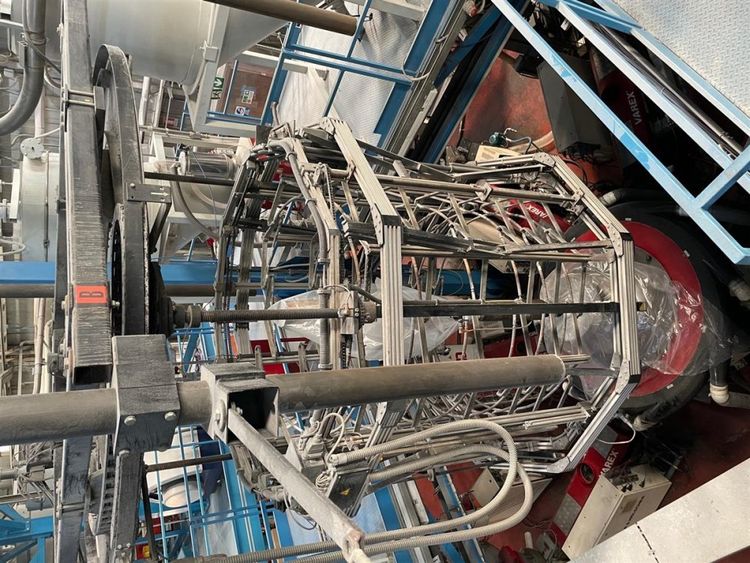

Head description IBC, OPTIFIL P2 automatic thickness profile control, auto width control via 3 ultrasonic sensors mounted on bubble cage

Die diam (mm) 500mm, gap 1.25mm and 2.25mm

Thickness controll system YES , 2 thickness gauges a. gauge beta control

b. Electronic system model HISCAN, year 2009 for measuring thickness

of overall film and of EVOH layer. Automatic thickness control OPTIFIL P"

Bubble cage Motorized position, rotating

Take off unit rotating

Corona treatment Double corona treatment

Web guide Yes

Rewinder Type Double Back to back

Rewinder max reel diameter 1200mm

Rewinder description . Surface or Gap winding. Reel unwinding and shaft extraction system. 3" and 6 " shafts

Note Euro Chiller