Wood Pellet Production Line

EUROPE (Western and Northern)

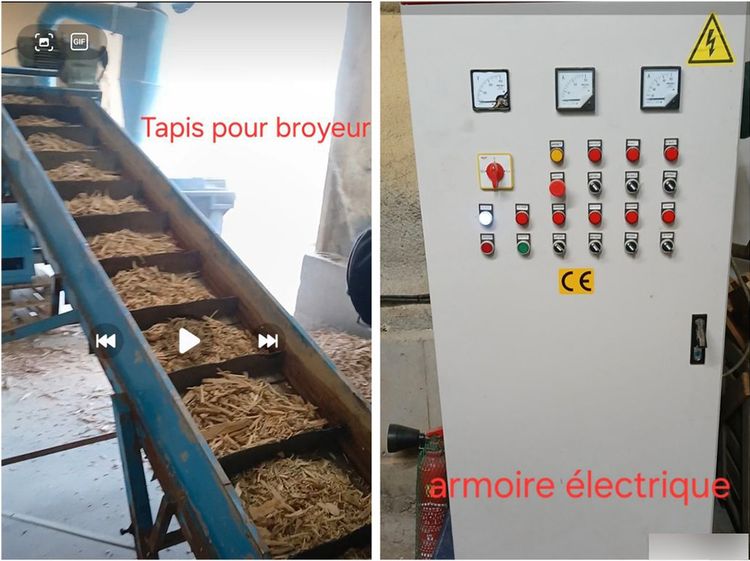

1- 3.5m conveyor belt to convey the raw material (wood chips) into the refiner-grinder with a variable speed drive.

2- Refiner-grinder: power = 7.5 kW, three-phase. Production capacity depending on the raw material: 300/500 kg/h to obtain 6mm sawdust - WEIGHT: 250 kg.

3- Hopper of approximately 2 m3 to convey the sawdust into the dryer. It is equipped with a variable speed drive to optimize the sawdust flow into the dryer according to its humidity.

4- Hot air flow dryer: power = 4 kW, three-phase, reduces the humidity of the sawdust by approximately 15% - Production capacity: average of 300 kg/h, equipped with a variable speed drive to adjust the fan speed, allowing for optimal management of the desired humidity level. Weight: 250 kg.

5- Two 1.5 kW auger conveyors

6- Two 750 W auger conveyors, one of which is equipped with a variable speed drive to manage the amount of sawdust fed into the pellet mill.

7- Pellet Mill Model: KAF 300 Power: 22 kW Amperage: 42 A Horizontal die: 300 mm. 2 rollers Pellet diameter: 6/8/10 mm Dimensions: 1.2 x 0.6 x 1.1 m Weight: 550 kg.

Its capacity (depending on material and die) is 200 to 300 kg for a raw material moisture content of 10 to 15% (hygrometer provided).

8- Screen cooler: The pellets leaving the presses are not dusted and can reach a temperature of +90°C. Pellets must be cooled and screened before storage or bagging.

Power: 2.2 kW (cooler) + 0.75 kW (screener). Capacity: 350 to 400 kg/h. Cooling and screening pellets is a crucial step to ensure a high-quality finished product.

9- Bucket elevator designed to transport pellets from the cooling screener to the bagging machine. 10- Semi-automatic bagging machine Power: 2.2 kW (sewing) - 2.8 kW (sealing) 380V 50Hz three-phase Compressor: 1.5 kW - Bag weight: 5-50 kg/bag - Packaging speed: 4 bags/min - Hopper capacity: 0.6 m3

This intelligent packaging machine is specially designed and developed for pellets. - Packaging system - Transmission system - Sealing system - Automatic weighing - Belt conveyor - Sold with 4000 bags with a capacity of 15 kg.

11- Electrical control cabinet - Pre-wired general electrical cabinet. Central control of the pellet production line. Equipped with 4 inverters: 1 to control the speed of the auger feeding the dryer and 1 for the grinder belt, 1 to manage the speed of the dryer fan

and one to manage the auger feeding raw material to the pellet mill.

This production line requires 36 kVA of electrical power to produce pellets (if you wish to grind and refine at the same time as pellet production, you must upgrade to the 42 kVA yellow tariff).

12 - 2 "Powercap Active" full-face dust masks

13 - Hygrometer, laser thermometer, grease pump.