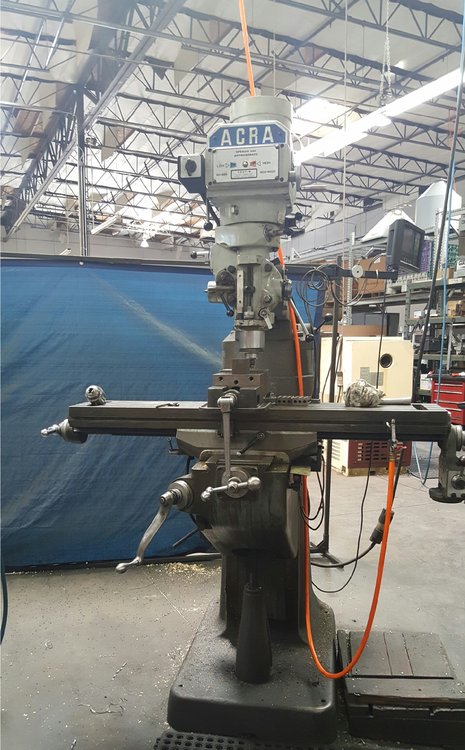

Acra Custom: Bridgeport vertical knee mill base with an Acra head

AMERICA North (USA-Canada-Mexico)

Specifications:

Table travel (X-Axis) 36”

Saddle Travel (Y-Axis) 12”

Quill Travel 5”

Knee Travel (Z-Axis) 16”

Ram Travel 12”

Throat Distance (Min.) 18.75”

Throat Distance (Max.) 6.75”

Standard 48” x 9”

T Slot center distance 3 @ 2.5” centers

T-Slot Size 0.625”

Cast Iron: 3/4"

Steel: 5/8"

Face Mill: 3"

End Mill: 3/4"

Spindle Taper: R8 Or Nt-30

Quill Diameter: 3-3/8"

Collet Capacity: 1/8" To 5/8"

Varaiable Spindle Speed: 60 To 4200 Rpm

Spindle Feeds: 0015, .0003, .0006 Inch/Rev

Spindle To Column: 5" To 17-3/8"

Motor: 3 Hp

Bridgeport Base

Table Size 9" x 42" or 9" x 49"

X-Axis Travel ~30"

Y-Axis Travel ~12"

Knee Travel (Z-axis) ~16"

Quill Travel ~5"

Spindle Taper R8

Manual Feeds X, Y, and Z via hand cranks

Power Feed (optional) May be installed on X-axis (varies by configuration)

Construction Cast iron for vibration dampening and rigidity

Acra Milling Head Specifications

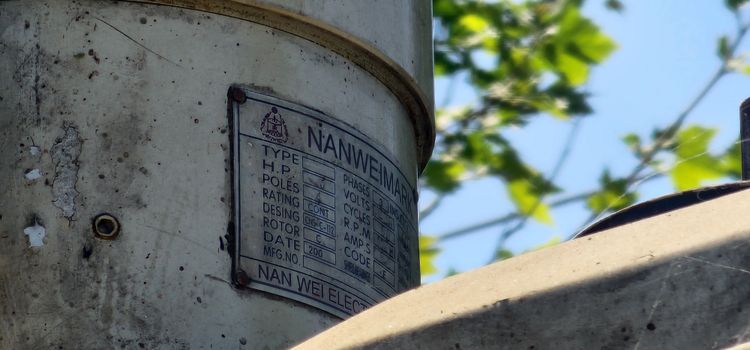

Spindle Motor 2 HP, 3-phase, 220/440V

Spindle Speed Range 60–4,500 RPM (variable speed)

Spindle Taper R8

Quill Feed 3-speed power downfeed (0.0015, 0.003, 0.006 in/rev)

Head Tilt ±90° left/right, ±45° front/back

Construction Meehanite cast iron head casing

Description:

Bridgeport-style vertical knee mill base that has been retrofitted with an Acra head—a fairly common and practical combination in machine shops when upgrading or repairing old Bridgeport machines.

________________________________________

Machine Overview

Base Machine: Bridgeport Vertical Knee Mill (Manual Mill Base)

Head: Acra Variable Speed Milling Head (Likely AM-2V or AM-2S)

________________________________________

Description – What It Does

This machine is a manual vertical milling machine used to:

• Cut, shape, and drill metal or plastic parts

• Perform tasks like face milling, slotting, keyway cutting, hole drilling, and contouring

• Handle prototype work, maintenance jobs, and precision machining of small to medium-sized parts

The Bridgeport base provides stability and smooth table movement, while the Acra milling head brings modern, reliable power and speed control.

________________________________________

Bridgeport Base Specifications (Typical)

Feature: Spec

Table Size: 9" x 42" or 9" x 49" (depends on model)

X-Axis Travel: ~30"

Y-Axis Travel: ~12"

Knee Travel (Z-axis): ~16"

Quill Travel :~5"

Spindle Taper: R8

Manual Feeds: X, Y, and Z via hand cranks

Power Feed (optional): May be installed on X-axis (varies by configuration)

Construction: Cast iron for vibration dampening and rigidity

________________________________________

Acra Milling Head Specifications (Assuming AM-2V or AM-2S)

Feature: Spec

Spindle Motor: 2 HP, 3-phase, 220/440V

Spindle Speed Range: 60–4,500 RPM (variable speed)

Spindle Taper: R8

Quill Feed: 3-speed power downfeed (0.0015, 0.003, 0.006 in/rev)

Head Tilt: ±90° left/right, ±45° front/back

Construction: Meehanite cast iron head casing

________________________________________

Capabilities

• Precision manual milling for small to medium parts

• Versatile use in maintenance, R&D, toolrooms, and prototyping

• Cuts steel, aluminum, plastics, and more with correct tooling

• Customizable with power feeds, DROs, or coolant systems

________________________________________

Listing Summary Description

Bridgeport Vertical Milling Machine with Acra 2 HP Head — This machine features the classic, rigid Bridgeport knee mill base with a modern, variable-speed Acra head retrofit. Ideal for precision manual milling, drilling, and light-duty shaping in maintenance or job shop environments. 9" x 42" table, R8 spindle taper, and 2 HP head with 60–4,500 RPM speed range.