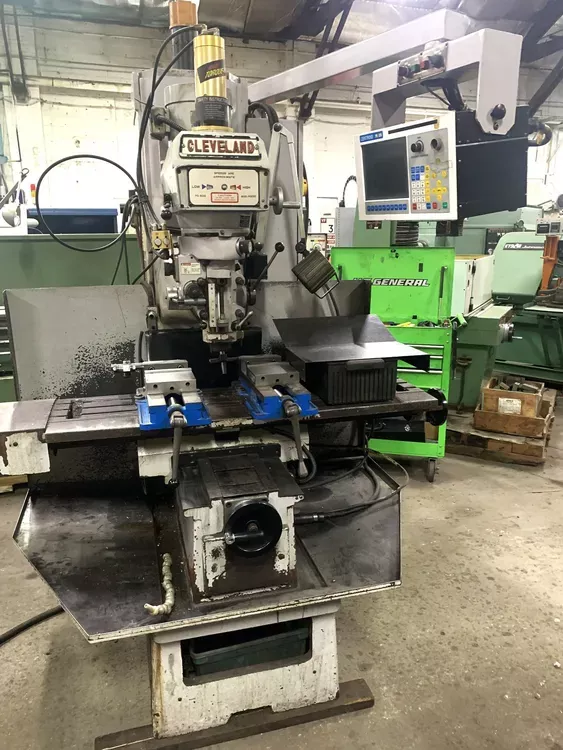

Cleveland B3VC Vertical 4000 RPM

AMERICA North (USA-Canada-Mexico)

CLEVELAND B3VC

Table Size 50" x 10"

T-Slot Size 3 x 0.63"

Max Table Load 1,000 lbs

X Travel 31.5"

Y Travel 16"

Z Travel 20"

Spindle Nose to Table 3.125" to 23"

Spindle Center to Column 17"

Spindle Taper NMTB 30

Spindle Motor 3 HP, 3-phase, 220V

Spindle Speed Low: 70–500 RPM

Spindle Speed High: 600–4000 RPM

Spindle Gear Ratio 8.4:1

Spindle Bearings Class 7 Super Precision 7210 Match Set

Spindle Quill Diameter 3.937"

Rapid Feed X/Y/Z 150 IPM

Cutting Feed X/Y/Z 120 IPM

Way Type Hardened and Ground with Turcite B Coating

Ballscrew Size X/Y 1-1/4", C3 Class Precision Ground

Position Accuracy ±0.0004"

Repeatability ±0.0002"

Coolant Pump 1/8 HP, 220V

Coolant Sump Capacity 7 gallons

Power Requirement 4 KVA / 15 Amps

Machine Weight Approx. 4,550 lbs

Floor Space 116" x 61" x 89"

Control CNC (CENTROID M15)

Control Display VGA LCD

Control Features 32-bit PC-Based DSP Technology

Updateable Software

High-Speed Block Processing

Internal Hard Drive

Digital Servo Drives and Motors

Splash-Proof Alphanumeric Keyboard

USB, Mouse, Parallel Ports

3-Axis Simultaneous Control

High-Speed 3D Contouring

CAD/CAM Ready

640kb Standard Program Size

Least Input Increment 0.0001" (0.001mm)

Emergency Stop

Backlash Compensation

Leadscrew Compensation

Smart Program Restart

Icon and Soft Key Operating System

MDI

Run Mode

Single Block Mode

Manual Feed (Jog)

Manual Pulse Generator (MPG Optional)

Sequence and N Number Search

Linear Interpolation G1

Rapid Positioning G0

Circular Interpolation G2/G3

Helical Interpolation G2/G3

Dwell G4

EIA FANUC-Style G-Codes

3D Toolpath Graphics

G-Code Backplot

Program File Name = DOS Legal

N Sequence Numbers with 9 Digits

Absolute/Incremental G90/G91

Inch/Metric G20/G21

Arc Radius R Value

Work Coordinate Options G28, G29, G30, G52, G53

Data Setting G10

Canned Cycles G73, G80–G83, G85, G89

Graphical G-Code Editing

3D Isometric and Tri-Planar Views

Pocket Milling (Circular and Rectangular)

Frame Milling (Circular and Rectangular)

Ramped Plunges

Auto Corner Radius

Subroutines (Copy, Repeat, Rotate, Mirror)

Tapping Cycles

Bolt Hole Circles

Boring Cycles

Auto Angle Calculator

Graphical Math Help with Paste to Event

Linear and Polar Value Support

Run Time Estimate

Includes Optional Power Draw Bar

Slideway Covers (Front and Back)

Tools and Toolbox

One-Shot Lube System

Safety Handwheels

Quill Handle

Operations and Parts Manual

Training Video Tape

Cutter Radius Compensation

Canned Milling and Drilling Cycles

200-Tool Library

Programmable Spindle Speed

Spindle Function S

G-Code Toolpath Graphics

Predefined M Codes

Part Program Storage and Editing