Nordson ULTRAFLEX R-75

AMERICA North (USA-Canada-Mexico)

EDI ULTRAFLEX R-75 EXTRUSION DIE 48″

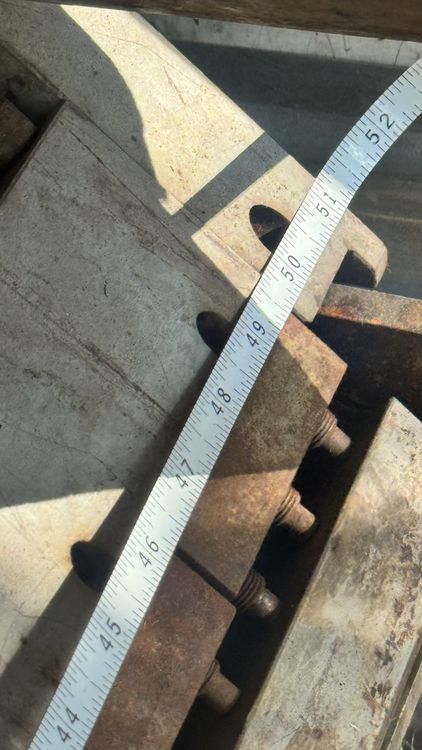

EDI Ultraflex R-75 Extrusion Die – 48″ Wide – S/N 88 11668

Specifications

Manufacturer: Extrusion Dies, Inc. (EDI) now part of Nordson

Model: Ultraflex R-75

Serial Number: 88 11668

Patent: US 3,859,032 (restrictor bar adjustment system)

Working Lip Width: 48″ (sheet width capacity)

Sheet Thickness Range: 0.050″ – 0.275″ (capable of producing up to ¼″ sheet)

Lip Style: Flexible upper lip with replaceable lower lip

Restrictor Bar: Internal, precision-adjustable via external studs/nuts

Heater Zones: Multi-zone heating system (band heaters and thermocouple ports included; condition to be verified)

Construction: Precision-machined tool steel die body

Feed Type: Back entry (single center feed port, to be confirmed)

________________________________________

Description – What It Does

The Ultraflex R-75 is a 48″ sheet extrusion die engineered to transform molten thermoplastics into flat sheet with excellent gauge control and uniform melt distribution. By combining a flexible lip design with a patented internal restrictor bar, the die ensures consistent quality across the full sheet width.

It is designed for medium-thickness sheet extrusion and has been proven in applications requiring ¼″ sheet products.

________________________________________

Capabilities

Produces sheet up to 48″ wide

Adjustable lip gap: 0.050″ – 0.275″

Produces sheets up to ¼″ thick

Handles a wide range of thermoplastics, including PE, PP, PS, ABS, and PVC

Multi-zone heating maintains uniform melt temperature across the die width

Flexible upper lip allows quick adjustments to correct thickness variations

Restrictor bar design ensures even polymer distribution

________________________________________

Core Functions

Melt Distribution: Channels molten polymer evenly across the full 48″ width

Gauge Control: Lip adjustment enables precise sheet thickness settings

Flow Balancing: Internal restrictor bar equalizes flow, preventing thick/thin streaks

Sheet Formation: Produces flat, uniform sheet suitable for cooling rolls or downstream forming equipment

________________________________________

Design Features & Benefits

48″ Working Width: Ideal for medium-format sheet production in packaging and industrial markets

Ultraflex R-75 Design: Proven EDI technology trusted across the industry

Flexible Upper Lip: Fine-tunes thickness while running, reducing downtime

Replaceable Lower Lip: Extends die service life and adapts to material changes

Patented Restrictor Bar (US 3,859,032): External adjustment system for quick, precise balancing

Multi-Zone Heating: Promotes consistent melt temperature and sheet quality

Heavy-Duty Construction: Long-lasting tool steel die body for continuous operation

________________________________________

Applications & Industries

Packaging – thermoforming sheet for food trays, lids, clamshells, and disposable containers

Construction – protective panels, liners, and rigid sheet products

Automotive – ABS or polyolefin sheet for dashboards, trims, and panels

Industrial Manufacturing – flat stock for machining, forming, or lamination

General Plastics Processing – multi-purpose sheet extrusion for PE, PP, PS, PVC, ABS

________________________________________

Machine Overview & Summary

This EDI Ultraflex R-75 extrusion die offers a 48″ sheet width capacity, adjustable lip range from 0.050″ to 0.275″, and proven ability to produce ¼″ thick sheets. With its patented restrictor bar system and flexible lip design, it delivers excellent gauge control, uniform distribution, and high-quality sheet production.

The die includes multiple heater zones and thermocouple ports (condition of elements to be verified). Its replaceable lower lip and durable construction make it a rebuildable, long-term asset for any sheet extrusion line.