Other TR 120‑49 / TR‑NS

AMERICA North (USA-Canada-Mexico)

Tria TR 120‑49 Granulator

Model: TR 120‑49 / TR‑NS

Manufacturer: Tria S.p.A.

Rotor Diameter: 490 mm

Rotor Width: 1,200 mm

Feed Opening: Approximately 970 mm wide × 120 mm high

Rotor Type: Open rotor with 5 rows of 2 knives (10 total)

Stator (Bed) Knives: 4 total (2 front, 2 rear)

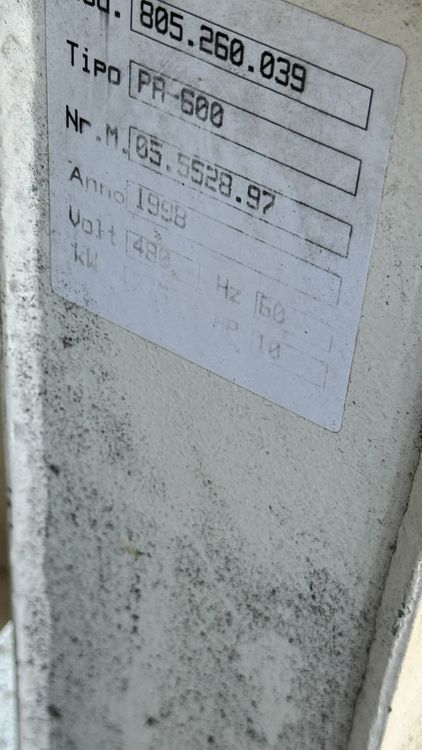

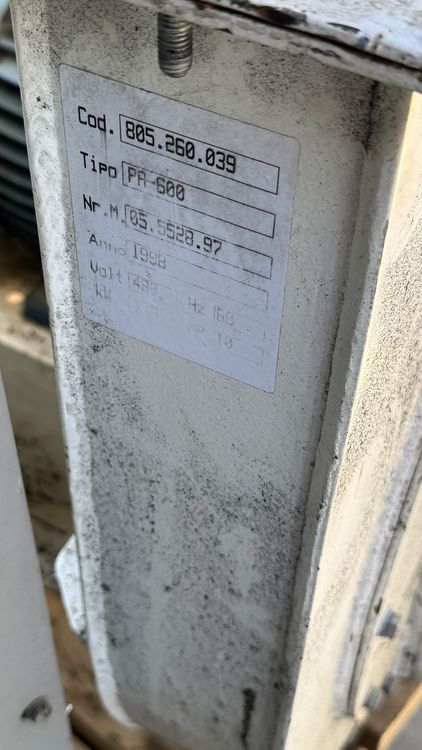

Drive Motor: 50 HP (approx. 37 kW)

Voltage: 460V / 480V, 3-Phase

Frequency: 60 Hz

Cutting Chamber: Water-cooled

Throughput Capacity: Up to ~1,200 kg/h (varies by material & screen size)

Construction: Soundproofed steel enclosure with hinged access doors

Screen Area: Large discharge screen for high throughput

Feed System: Rear trap-door (ideal for thermoforming line integration)

Knife Material: Tungsten-tipped for extended wear life

Noise Reduction: Fully enclosed sound-insulated casing

Applications: Inline or central granulation of PET, PP, PS sheet, and thermoformed scrap

Description:

Machine Overview

Model: TR 120 49 / TR NS (Tria TR Series) — specifically designed for shredding full sheet thermoformed material (e.g. PP, PS, PET) inline on thermoforming lines or as a standalone granulator with rear trap door feed.

Equipped with a sound proof cabin, it includes a water cooled cutting chamber and tungsten tipped knives for enhanced wear resistance.

________________________________________

Key Specifications (typical for this model)

Rotor Diameter: 490 mm

Rotor Length: ~1 200 mm

Feed Opening (WxH): ~970 mm × 120 mm

Power: 50 HP (~37 kW)

Voltage 480 V three-phase (often 460 – 480 V)

Throughput Capacity : ~1 200 kg/h (depending on material type and screen size)

Rotor Knives 10 knives arranged in rows; 5 rows of two each

Stator (Counter) Knives 4 total (two front, two rear)

Cooling System Water-cooled cutting chamber

Soundproofing Fully enclosed casing reduces operator noise

________________________________________

Design Features & Benefits

High throughput: Large rotor diameter and wide infeed enable processing up to ~1.2 tons/hour of thermoformed scrap.

Efficient cutting: The 50% screen area relative to rotor circle allows rapid discharge, minimizing dwell time and fines.

Robust wear protection: Tungsten tipped blades and hardened chamber surfaces extend service intervals.

Precision gap control: Pre-set blades with gauge ensure consistent knife-to-screen clearance, easing maintenance.

Inline compatibility: Rear trap-door feed is ideal for inline thermoforming integration; designed to synchronize with extruded/reel-fed lines.

Operator safety & comfort: Sound-insulated housing and cooled chamber reduce noise exposure and dust.

________________________________________

Applications & Industries

Thermoforming Waste Recycling: Sheet feeders of PP, PS, PET; trimming scrap and trays directly from forming lines.

Tray & Container Regrind: Ideal for sheet and tray recycling in inline or centralized systems.

Plastic Recycling Plants: Secondary reduction of thermoforming scrap or post-consumer rigid plastics.

In Plant Granulation: Inline feeding of heavy sheet scrap into granulators with blower or suction systems.

Packaging & Beverage: PET tray and sheet processing in packaging operations.

________________________________________

In Summary

The Tria TR 120 49 / TR NS is a high-performance, industrial granulator engineered for high-speed sheet and thermoforming scrap reduction. It excels in inline and centralized operations for PET, PS, and PP, combining:

490 mm rotor,

1,200 mm length,

50 HP motor,

~1,200 kg/h throughput,

durable wear parts,

soundproof, cooled enclosure,

Efficient inline feeding options.