PLASTICISERS Staple Fiber Line revised in 2020

AMERICA North (USA-Canada-Mexico)

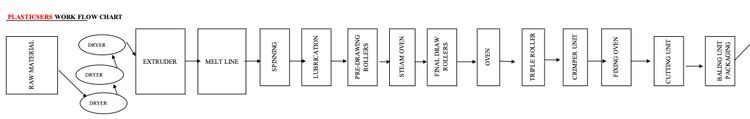

STAPLE FIBER PROCESSING LINE

Input Material Virgin/Recyle poliproplene and polyester

Brand Name PLASTICISERS

Model 1992/revised in 2020 (new dryer, all DC motors were converted to AC, the crimper was upgraded, the dryer was converted to PLC, the spinnerets were converted to cylindrical from rectangle, etc)

Capacity Approx. 650 kg/h

Extruder 160 mm single screw

Feeding 4 dry compressed air type driers

Dosing 6 positioned Conair Churchill dosing unit for masterbatch and additives

Spinning 4 round solid type spinnerets

Drawing 3 units

Spinfinish appplication

Kiss roll type with preparation tanks equipped with heaters and agitators

Steam Box 2 units

Crimper 200 mm chamber width

Final chemical dosing available

Driyer 2 gas burners, 3 ventilation fans with cooling section

Cutter

cutting wheels and pneumatically actuated nip roll, various cutting lengths

Bale press Twin box vertical type hydrolic bale press

Status still on production (Oct 2022)

Consisting of:

1 x Extruder – 160mm single screw

4 x Dry compressed dryers for feeding

1 x Conair Churchill dosing unit – 6 positions – masterbatch and additives

4 x Spinnerets – round type

3 x Drawing Units

1 x Kiss Roll type spinfinish application w/ preparation heated tanks and agitation

2 x Steam boxes

1 x Crimper – 200mm width

1 x Final chemical dosing

2 x Gas burning dryers, 3 ventilation fans with cooling section.

1 x Cutter

cutting wheels and pneumatically actuated nip roll, various cutting length

1 x Twin box vertical type hydraulic bale press

Chiller 125,000 kcal, Conair churchill

Fiber denier range 4-30

Fiber length 26-150mm

Energy consumption 320 kw/h

4 workers

Dimension: width 12m, height 7m, length 70m

* The lines work with pet flakes, pet granules/pellets, pet virgin materials as well as pp.

* For PP granules Grade/MFI? 20-25 mfi

* Tenacity of fibre along with elongation for PP and Polyester?

2,8-3,8 cN/dtex

* Godet diameter 320 mm, oil heated most of the motors are AC type

* Mostly chrome finish godets

* Double piston type continuous melt filter with large filtration area equipped with venting system

* Spares: 1 whole set of spare spinnerets, 4 cutting disks for different cutting lengths

* input material dryers are before extrusion and before spinning.

* Spinnerets as diameter and number of holes are same for polyester & pp fiber.

* Spun TOW collection system? It is automatic continuous production line.

* Vacuum cleaners for Spinnerets?

There is vacuum in positions where you place spinnerets.

* Drawn fibre Relaxor oven length (with maximum resilient time)?

For plasticisers: 7 x 3 meters

* Type of Baler, with maximum bale weight? Twin cabinet, 280 kg/bale

* 440 or 380V used? 380 V

* The dryer automation is converted to PLC.

* New dryer has been bought with energy saving property.

* DC motors are converted to AC.

* The crimper has been renewed.

* The spinneret positions have been converted to cylindrical shape from rectangle.

* Motors and drivers are updated to AC.

Energy consumption: 650 kw/h

Worker /shift: 4 worker

Fiber Denier Range 4-30 denier

Fiber Length 26-150 mm

Width 12 mt

Height 7 mt

Length 70 mt

Also available but optional

The chiller of Plasticisers:

Brand Conair Churchill

Model FFA 140

Capacity 125.000 kcal

The boiler :

Brand Ozmaksan

Model 2015

Capacity 2000 kg/h

Pressure 6 bar

Fuel type Gas/ liquid

The laboratory testing equipments:

Light cabinet

Precision scale

Microscope

Tensile measurement machine

Etuv

The referenced line is not suitable for filament yarn

New video: https://youtu.be/1T9uF3kX_44