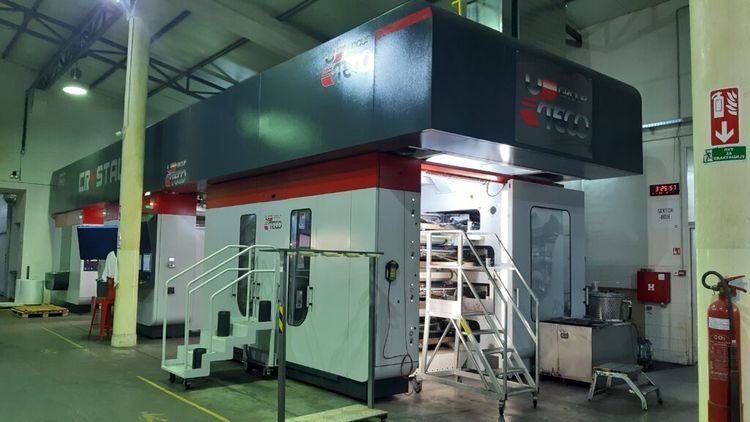

Uteco CRYSTAL 808 8 1500 mm

EUROPE (Western and Northern)

Color 8

Speed 500 m/min

Max. Size 1500 mm

Condition Good

Central Drum Flexographic Press (Model 150)

Printing Stations: 8 units (8+0 configuration) – can print up to 8 colors at once

Drive Type: Gearless (each printing & anilox cylinder driven by its own motor, no mechanical gears)

Max Printing Width: 1500 mm – width of the printed area

Max Material Width: 1550 mm – maximum film width the machine can handle

Printing Repeat Range: 400–850 mm – adjustable repeat steps

Max Speed: Mechanical: 500 m/min; actual speed depends on inks and material

Ink Type: Solvent-based, explosion-proof design

Materials Supported: PP, BOPP, LDPE, CPP, HDPE, PET, OPA films – thickness 10–200 µm

Tension Range: 2–36 kg – web tension during printing

Unwinder/Rewinder: Automatic turret type TAR-N 1000 – allows reel changes at full speed

Web Infeed Group: Edge guiding system, corona treatment, reprint capability

Central Drum: Ø 1862 mm Hastelloy coating – corrosion resistant

Colour Units: Sleeve system for quick change, automatic pressure adjustment (Touch & Go, Kiss & Go)

Drying Section: Between-color drying, 5 m tunnel, hot air gas burners, LEL solvent monitoring

Outfeed Unit: Chill rolls to cool the material, nip roller, video inspection systems

Automation & Control: B&R PLC, remote assistance, data storage for 5000 jobs, USB export

Register Systems: Automatic longitudinal and side register controls

Inspection Systems: Grafikontrol PROGREX 500 and Lynex – 100% defect detection

Installation Requirements: 400V 3-phase power, 6 bar compressed air, 15–18°C chilled water

Environment: Temperature 10–40°C, humidity 30–80%, altitude ≤1000 m

Automatic Turret Unwinder & Rewinder (TAR-N 1000) – reel changes at full speed

Web Infeed Group – edge guide, corona treatment (Ferrarini & Benelli), reprint system

Colour Units – sleeve system for quick change, P2P pressure compensation, Touch&Go, Kiss&Go automatic pressure/register setup