Voith Complete Speciality Paper Machine ( Base for coating, Fluting, P&W ) 2.800 mm 45 to 300 gsm 110 TPD

EUROPE (Western and Northern)

Maximum speed 500 m/min, gsm range 45 to 300.

Maximum reel weight 6000 Kg.

Products: Printing and writing, base for coating. Fluting.

Production: 770 t/week (average). Drive on left from flow box.

Sectional electric drive: DC Emmerson manufacture, year 2015.

Stock preparation approach flow

External mild steel starch tank and concrete water tank

Pulp bale line with de wiring station

Wire baler

Hardwood line with stainless steel Grubbens pulper.

Inclined feed conveyor

Softwood line with stainless steel Grubbens pulper.

Both pulpers have low consistency batch operation. V belt drives.

Area covered by 32-ton crane.

Titanium make up plant now no longer in use.

ELCO 1250mm roll splitter width on input conveyor to Grubbens broke pulper.

Refining by three JCO-1 refiners, Beloit 4000 series refiner, Jyhavara DD720 and one JCOO deflaker.

Concrete stock chests with vertical agitators

Back water fibre recovery by Holder drum thickener

Various chemical tanks (Nalco, felt cleaning).

Deculator which is no longer in use complete with LD cleaners.

Two DSM slotted screens for fibre water recovery, stainless steel

Concrete machine chests.

Six Nash Vacuum system with 3002 and 2002 pumps.

Jyhavara CI lined pressure screen with rejects to Voith vibrating screen.

Four stage Celleco LD cleaners.

PCC tanks and two in-line stainless filters.

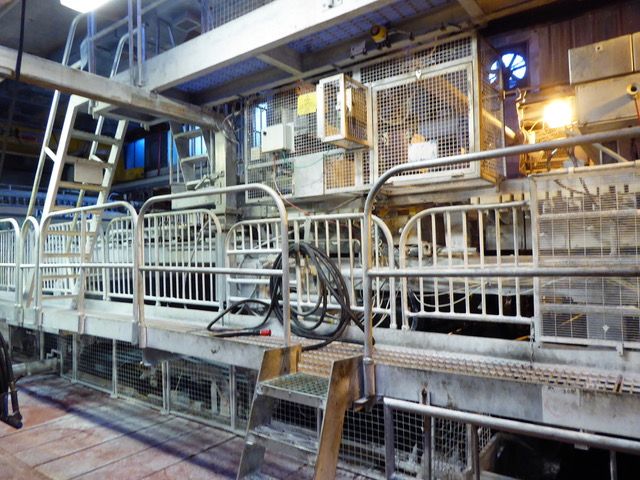

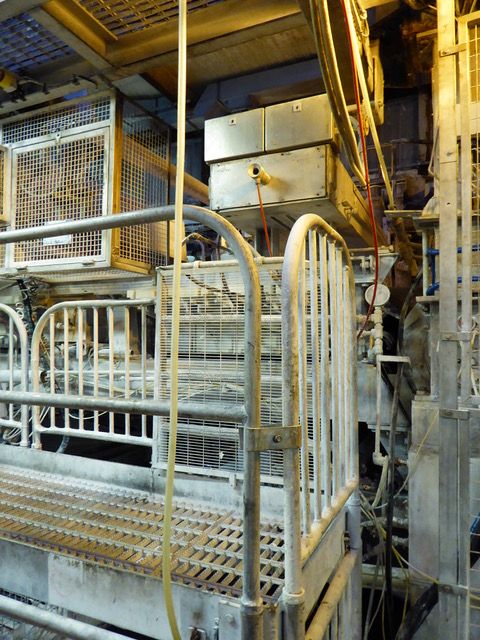

Paper Machine

Wire

Voith step diffuser flowbox auto profile control, dilution control, stainless steel, complete with dilution control, two holey rolls.

Stainless cantilevered wire part, foils, dandy, vacuum boxes, tail cutter.

Steam box on couch, 18m centres from breast roll to forward drive roll.

Presses

Suction pick up

Sandusky first press

Second plain press

Third smoothing press

Guides Thune design.

Drying section

CI drying cylinders with A/F bearings, CI open gear drive, turbo internal bars, auto lube system, rated at 45 psi pressure operating, diameter 1219mm, sheathen rope rings, Thune automatic felt guides,

Thirty six pre dryers

In-line moisture gauge

Size press horizontal with micro rock and micro mate rolls, pneumatic loading.

Size tanks with two Celleco screens.

After dryers 14 off

Calendar Kuster sack with two Kuster rolls

Hole detector.

ABB scanner measuring profile, gsm, calliper, ash and colour year 2015

IBS tape tail transfer.

Horizontal reel up for 1500mm diameter rolls.

Core/shell extraction unit.

Broke pulper with conveyor, batch operation, in-line Jyhavara roll splitter year 1972 for 1250 mm rolls.

Rewinder: Jagenberg Vari-Step, eleven slitters, fixed unwind with shaftless rewind. Single motor drive, voltage 415V, reel ejection and lowering table. Auto knife set.