Voith complete Twin wire paper machine 2600 mm 110-210 gsm 350 TPD

EUROPE (Western and Northern)

Maximum speed: 1000 m/min

Product paper grades: Semi-chemical, Test Liner, Wet-resistant

STOCK PREPARATION

Three pulpers with their conveyor belts:

Pulper 1: Manufacturer: Voith, Low Density, 10 m3

Pulper 2: Manufacturer: RCM, Model: HD20, High Density, 20 m3

Pulper 3: Manufacturer: RCM, Model: HD20, High Density, 20 m3

After the Pulper Zone, the rest of the Stock Preparation consists of a Protector System-Voith, a three-stage Coarse Screening section, a fiber separation section, and finally a thickener dedicated to the bottom line. The stock preparation line was completely revamped between 2021 and 2022.

APPROACH FLOW: This consists of two separate lines for the top and bottom layer. Both lines use screens and low-consistency cleaners for further cleaning of the stock. After cleaning, the furnish is pumped into the headboxes by fan pumps.

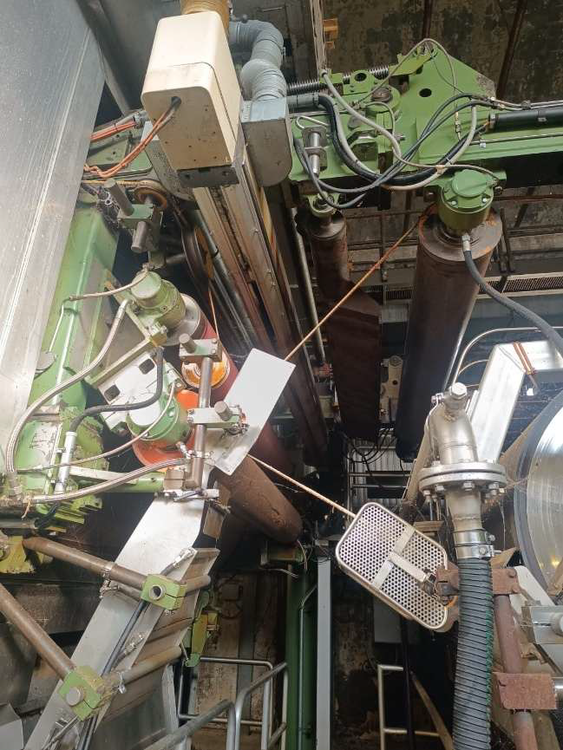

PAPER MACHINE: It consists of two forming wires with two Voith headboxes,

one for the top and one for the bottom layer, a wet press section, a pre-drying section, a Size Press, a post-drying section, and a Pope winder.

The pre-drying section is divided into five batteries, for a total of 42 dryer cylinders and nine vacuum rolls. The first two batteries are slalom-type, while the remaining batteries are double-felted.

First Measuring Bridge: Manufacturer: Honeywell, Measured Values: moisture

Size-Press: Manufacturer: VAS

The post-drying section is divided into two batteries, for a total of 18 drying cylinders. Both batteries are double-felted.

Second Measuring Bridge: Manufacturer: Honeywell, Measurement values: moisture, grammage

Pope reel: Manufacturer: VAS

Rewinder:Manufacturer: VAS

Maximum speed: 2500 m/min

Additional description: Equipped with: 4 knives (3 sizes), New Aerodinamica dust extraction and abatement system

Water Treatment

Flotator: Manufacturer: OMC