Welex HS 3.0 40D SV

AMERICA North (USA-Canada-Mexico)

Specifications:

Serial #8454

Model HS 3.0 40D SV

Used 3" Welex 40/1 L/D

Extruder diameter- 3″

L/D ratio 40/1

Type: Vented/Plugged,

high speed, single screw

extruder

Year of manufacture:

New 5/2009.

Has electric heated and air cooled barrel

57" barrel center line

Height 3" x 9" oversized water cooled feed throat

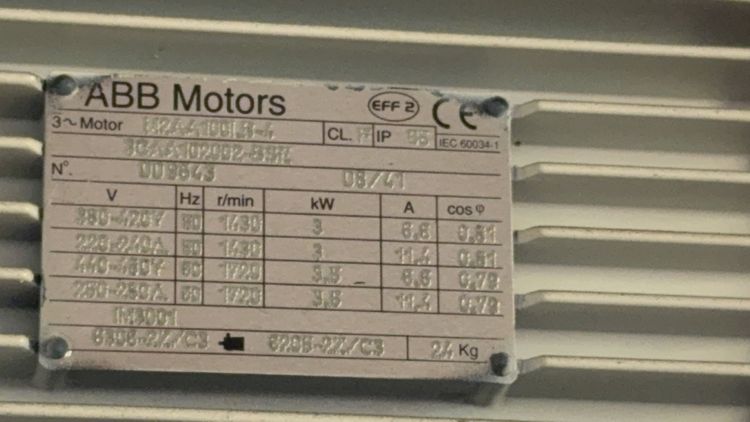

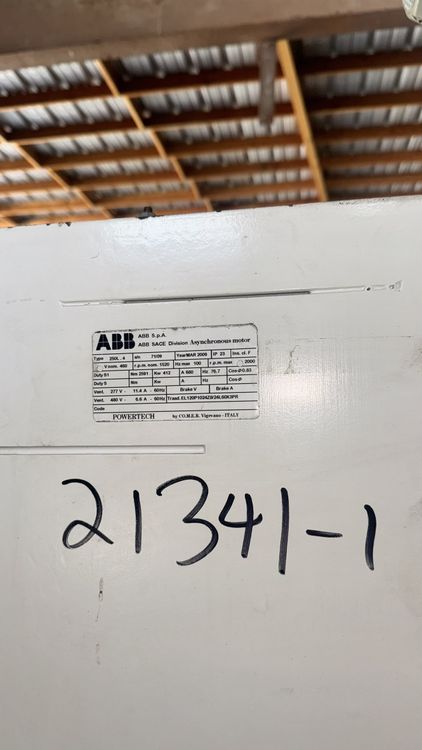

Direct driven by a 412

KW ABB AC motor with ABB Variable Frequency

Drive 680 amp 480 volt input.

480 volt/3 phase/60 Hz

(VFD 680 amp)

Motor- A.C.- 412 Kw/550

horse power (direct drive)

Touch screen operator control.

Maximum 1520 Screw Speed

Condition: Excellent

Description:

The Welex Model HS 3.0 40D SV is a high-performance, single-screw plastic extrusion machine designed for continuous processing of thermoplastic materials. Known for their rugged construction and precision control, Welex extruders are widely used in applications such as sheet extrusion, profile extrusion, and compounding.

________________________________________

What It Does

Melts and homogenizes plastic resins (pellets, granules, or powders)

Pressurizes and conveys molten polymer through a die

Forms continuous plastic products like sheets, films, or profiles

It’s ideal for operations that require high-output, precision melt control, and consistent quality over long runs.

________________________________________

Key Specifications & Features

Model: HS 3.0 40D SV

Screw Diameter: 3″

L/D Ratio: 40:1 (Long barrel for better mixing and output)

Drive Type AC or DC motor drive (varies by version, typically 50–100 HP)

Barrel Heating Zones: Typically 5–7 zones with PID control

Cooling System: Air or water-cooled barrel zones

Output Capacity:~300–600 lbs/hr (varies by resin and configuration)

Material Types PP, PS, ABS, PET, PVC, PE, and other thermoplastics

Feed Type Gravity feed (hopper-fed), with optional vacuum loader

Control System: Standalone operator panel with temperature & motor controls

Die Compatibility: Designed to connect to sheet dies, profile dies, etc.

________________________________________

Capabilities

High L/D Ratio (40:1):

Superior mixing

Higher output

Better melt homogeneity

Efficient devolatilization (if vented)

3″ Diameter Screw:

Sheet extrusion (e.g., thermoforming sheet)

Lab or pilot-scale compounding

Robust Gearbox & Bearings:

Flexible Temperature Control:

Multi-zone barrel heating ensures precise melt temperature regulation for a wide range of materials.

________________________________________

Applications

Plastic sheet extrusion (for thermoforming, packaging)

Profile extrusion (window frames, tubes, trims)

Masterbatch or compound production

Custom extrusion lines (when paired with downstream equipment like screen changers, dies, chill rolls)

________________________________________

Summary Description

The Welex HS 3.0 40D SV is a 3″ single-screw plastic extruder engineered for high-output, high-precision extrusion applications. With a long 40:1 L/D screw, robust drive system, and multi-zone barrel heating, it's capable of processing a wide range of thermoplastic resins into continuous forms such as sheets, profiles, and compounds. Built for reliability and consistency, this extruder is ideal for demanding industrial operations.