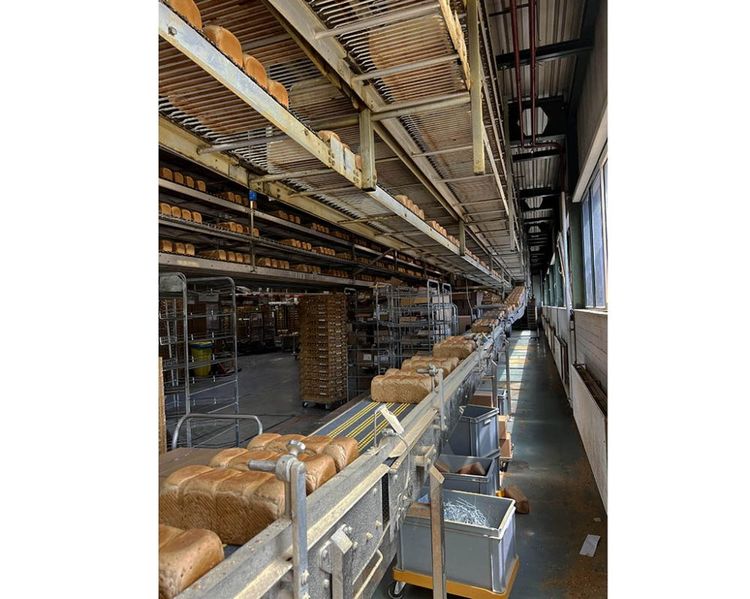

Benier Toast Bread Line

EUROPE (Western and Northern)

Brand Benier, Den Boer, Hartmann, Tromp

Capacity approx. 2,300 units per hour

Manufacturer: Benier, Tromp, Winkler den Boer, Hartmann

Year: Various, 2001 – 2024

Capacity: approx. 2,300 units per hour

Industrial large-batch bread production line, consisting of:

Dough preparation system, consisting of, among other things:

• 3 pc. spiral mixing machines, type SP 160 E, including bottom discharge, drum extraction, sensors, etc.;

• 1 standard wagon transport, 4 stops, including standard wagons, rails, sensors, etc.;

• 1 platform, stainless steel, including steps and safety fencing;

• Various controls, couplings, safety devices, etc.

Dough processing system, consisting of, among other things:

• Vemag portioning machine, type HP 20 E, incl. standard lifting/tilting trolley, device, safety gates, digital control, sensors, etc.;

• Checkweigher, stainless steel, incl. rejection device and AllScales; control scale, type WS-II;

• Benier conical rounding machine, stainless steel type Allround, incl. cone heating and Teflon-coated chute;

• Benier intermediate proofer, capacity approx. 2,300 pieces/hour

– 8 rows, 9 feet

– stainless steel

– heated by central heating system, incl. Lauer

– conveyor belt infeed

– platforms

– climate control

– digital control, etc.;

• Metaflex panel enclosure for ball cabinet, stainless steel, incl. 2 doors, cage ladder, etc.;

• Ammeraal Beltech conveyor belt, length 800 cm, incl. stainless steel covers;

• Benier dough moulder, incl. dough infeed conveyor, centring roller, drag net, pressure plate, dough dividing blades, 4-piece & twisting device, coupled conveyor, sensors, controls, etc.

Capway linear proofer, consisting of:

• Oval linear conveyor, 9 tiers, total length approx. 540m, incl. platforms, curves, switches, etc.;

• Panel enclosure, incl. 2 doors, 1 window, etc.;

• Climate control system, controls, wiring, etc.;

• Tromp decorating conveyor, incl. conveyor belt, water spray system, platform, 7c pc. seed scattering units, 1 flower scattering unit, sensors, controls, etc.;

Lidding system, consisting of:

• Lidding machine, incl. Siemens digital control, type Simatic touch;

• Lid transport system, incl. robot, lid magazine, etc.;

• Delidding machine;

• Venema waterjet cutting robot, type Decojet, stainless steel, incl. Fanuc;

• Robot, type M-710iC50, Safety fence, three cutting heads, etc.;

• Robot controller, type Robot Controller R-30iA, incl. water pressure, compressor, frame, pipes, etc. (installed in the basement of the packing room).

Winkler Den Boer tunnel oven consisting of:

• Oven loading device, incl. coupled feed conveyor, length approx. 16 m, incl. 3 x 90° bends, etc.

• Wiremesh belt tunnel oven, belt size 2,300 x 330 cm, indirectly heated, incl. control, etc.;

• Oven unloading device, incl. bread spray system, extractor hood, etc.;

• Certus Steam boiler, type E72M, incl. expansion vessel, efluent collection tank, lift pump, pipes, fittings, etc. (installed in the basement of the packing area).

Divardy; needle depanner, stainless steel, incl. safety gate, coupling conveyor, bread conveyor belt, etc.

Capway baking strap conveying system, consisting of:

• Conveyor belt, approx. 60 meters long, incl. 7 x 90° bends, 1 S-bend, etc.;

• Cooling tunnel belt, incl. extraction, etc.;

• Cleaning system, type Cleancap, incl. tin brush;

• Tin greasing machine, incl. extraction.

Capway strap storage system, type Robocap, capacity approx. 6,000 straps, incl. overhead rails, robot, control cabinet, fencing, safety devices, etc.;

Capway product cooling conveyor system for large-loaf bread, from depanner to packaging line, 4 tiers, total length approx. 985m, incl. curves, switches, transfers, etc.;

Mettler Toledo metal detection system, type Viper BC, incl. rejection device with chute, conveyor belt, controls;

Jasca; cold-water misting system, type JC-LDV, incl. pipes, controls, misting nozzles, etc.;

Prepac inline desinfection tunnel, type Sunoven, type SU-110-A-2, incl. digital controls (not installed, available from stock)

Toast bread packaging system, consisting of:

• 2 pc. Hartmann conveyor belts, length 2 x 280 cm, belt width 40 cm;

• 1 pc. Hartman bread slicer, type Slicer Selectra 30, incl. infeed conveyor, length 240 cm;

• 1 pc. Hartmann bagloader, type GBK 420, incl. infeed conveyor, with half loaf splitter, clip- band closer, etc.;

• 1 pc. packaging belt, length 460 cm, incl. base cabinet;

• 2 pc. VWS Netherlands Labeling systems, type LP500-Twin, incl. 4 label printers, type LP500 blow, central control, type Octopus, etc.