Maag Alinox CSC-149

AMERICA North (USA-Canada-Mexico)

MAAG CSC-149

Machine overview & summary

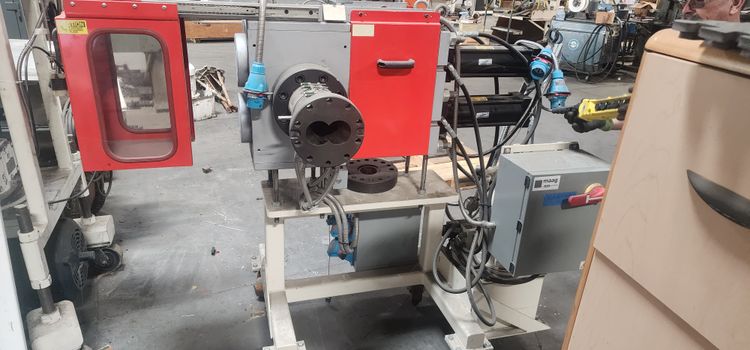

Used MAAG Continuous Screen Changer

Model: CSC-149 (CSC series, double-piston continuous screen changer).

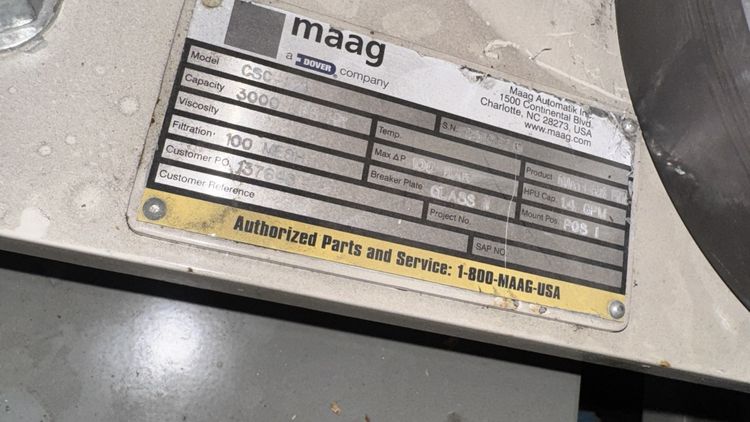

Serial / nameplate data you provided: Manufacture Aug-2018, Drawing 134.5436.901, SAP 724104, Serial VA18067 / 50163718, Capacity ~3,000 lb/hr (≈1,360 kg/hr), 100 mesh screen, Breaker plate Class 1, Mount Pos POS-1, HPU 14 GPM. The CSC-149 corresponds to MAAG’s ~148 mm piston size family in the CSC product line (see MAAG throughput/area tables below).

________________________________________

Key specifications (MAAG published & unit nameplate)

Manufacturer: MAAG (Maag Pump Systems / Maag Automatik).

Model: CSC-149 (CSC series — double-piston continuous screen changer)

Serial / Plate: VA18067 / 50163718 (as photographed)

Drawing No.: 134.5436.901 (as provided)

Manufacture Date: Aug-2018 (nameplate)

Nominal throughput (your plate): 3,000 lb/hr (~1,360 kg/hr) — matches MAAG’s 148 size throughput range for CSC classic/PE variants.

Screen / Filtration: 100 mesh (nameplate)

Breaker plate: Class 1 (nameplate)

Mount position: POS-1 (nameplate)

HPU (hydraulic power unit) capacity: 14 GPM (nameplate) — used to operate the pistons/switching.

Typical CSC-148 (MAAG published) screening details (for reference): Screen diameter 148.3 mm; filtration area (classic) 2 × 173 cm²; throughput ranges depend on engineering variant — Classic ~500–1,400 kg/h, PE variant up to ~1,100–3,200 kg/h and R versions even larger. Your 1,360 kg/h figure fits comfortably in the CSC-148 / PE throughput window.

________________________________________

MAAG published performance / limits (from MAAG CSC datasheet)

Application temperature: up to 350 °C (typical CSC versions). Operating pressure (standard): 500 bar (typical published limit for CSC classic). Option: high-pressure up to 700 bar available as an upgrade on some executions.

Pressure differential (ΔP): up to 200 bar for high-pressure breaker plates (classic / PE). Standard ΔP limits vary by design (MAAG datasheet lists pressure differential ratings and options).

________________________________________

Dimensions & weight

MAAG datasheets give piston/screen diameters, filter areas and throughput ranges but do not publish a single standard “weight” for every model because configurations (heater jackets, support frames, HPU, special coatings, candle filters, etc.) vary. Example market references for similarly sized CSC 148/230 show typical installed weights in the ~700–1,650 lb (320–750 kg) range depending on execution (heater jackets, support frame, HPU included). Use the table below as an estimate only — confirm exact weight/dimensions when quoting transport/lifting.

Typical filtration area (CSC-148, classic): 2 × 173 cm² (≈346 cm² total active area).

Typical throughput windows (examples):

CSC classic 148: ~500–1,400 kg/h (≈1,100–3,080 lb/hr).

CSC PE 148: ~1,100–3,200 kg/h (≈2,420–7,050 lb/hr).

Typical installed weight (installed unit w/ HPU & base): ~700–1,650 lb (rough market reference; confirm).

________________________________________

What it does

The MAAG CSC (continuous screen changer) performs continuous melt filtration for thermoplastic melts. Using a sealless double-piston design, it allows one piston (or pocket) to be taken out/cleaned while the other continues filtering — therefore the production line never needs to stop for a screen change. It removes gels, debris and contaminant particles from the melt stream to protect downstream gear pumps, pelletizers and dies, and to improve product quality.

________________________________________

Core functions & capabilities

Continuous filtration (no production stop during screen change).

Filtration fineness to 100 mesh (as fitted). (Screen packages can be customized.)

Breaker plate assembly to hold screen packs in position and control melt flow.

Hydraulic piston switching (driven by an HPU — your unit lists 14 GPM).

Short melt residence time and sealless piston design for leak-free operation and reduced degradation risk.

________________________________________

Design features & benefits

Sealless double-piston design — very low leakage risk and high reliability

Compact mounting & short melt-residence — can be mounted directly to downstream equipment to minimize dead volume

Multiple configurations — Classic, PE (area optimized), R (large area / curved screens), candle filter versions and optional backflush or high-pressure packages.

Upgradable — options for higher pressure (up to 700 bar), high-temperature finishes, special coatings, and stainless steel designs for aggressive applications.

________________________________________

Typical applications & industries

Polymer compounding (masterbatch, fillers, additives).

Film/sheet extrusion, pipe/profile extrusion, fiber production.

Pelletizing and strand/pellet lines.

Recycling (re-process and filtration of regrind).

Hot-melt adhesives and other high-temperature polymer processing where continuous filtration is required.

Full spec data

MAAG’s CSC literature gives general specs; for the CSC-149 specifically:

Filtration area: 2 × 149 cm² per screen (hence the “149” in CSC-149)

Max melt pressure: up to 500 bar (~7,250 psi) depending on polymer, breaker plate & screen pack

Max melt temperature: up to 350 °C (662 °F) standard; higher with special materials

Hydraulic pressure for actuation: ~200 bar (~2,900 psi) typical

Weight: ~600–700 kg (screen changer block only); with HPU ~900–1,000 kg

Dimensions (screen changer block): approx. 1,100 mm L × 550 mm W × 600 mm H (43″×22″×24″); your tape measure photos line up with this footprint

Breaker plate diameter: ~150 mm (5.9″); your measurement shows the twin flow ports around 6–7″ center-to-center

Connection ports: DIN or ANSI flanges; double-oval melt channel pattern visible