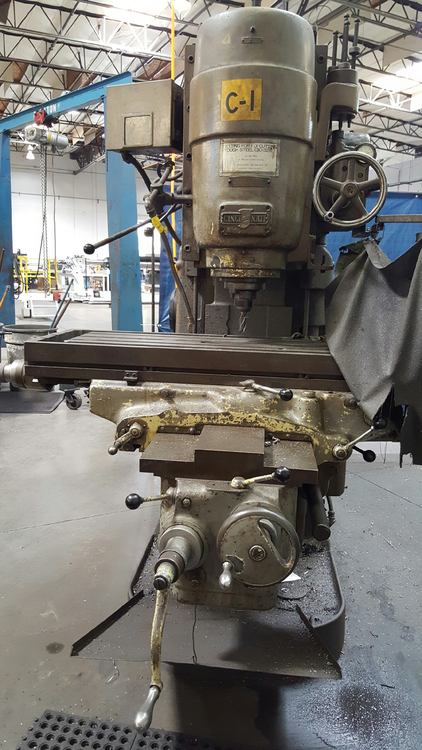

Cincinnati Model 3 Vertical Milling Machine Manuel

AMERICA North (USA-Canada-Mexico)

Specifications:

Cincinnati No. 3 Vertical Milling Machine – Serial 4A3V5A-7

Manufacturer: The Cincinnati Milling Machine Co., Cincinnati, Ohio, USA

Year Built: 1953

Electrical: 440V, 3-phase, 60 Hz (Control voltage: 110V AC)

Type: Heavy-Duty Knee-Type Vertical Milling Machine – Dial-Type

Specifications

Table size: 62.5" × 15.25"(T-slotted)

Longitudinal travel: ~34"

Cross travel: ~12"

Vertical (knee) travel: ~20"

Spindle taper: NMTB 50

Spindle speed range: ~15 – 1,500 RPM (16-step Dial Selector)

Spindle motor: ~10 HP AC

Feed rates: 0.5 – 20 in/min (power feed)

Rapid traverse speeds: Longitudinal ~100 IPM, Cross ~100 IPM, Vertical ~80 IPM

Machine weight: ~9,500 – 10,500 lbs

Floor space: ~8.5 ft × 9 ft

Key Features

Dial-type speed selection for quick spindle changes

Heavy-duty gear-driven feeds on all axes

Rapid traverse to reduce non-cutting time

Rigid overarm and spindle support for heavy cuts

Large table capacity for big work pieces and multiple setups

50 taper spindle for high torque tooling

Typical Applications

Mold and die base machining

Large fixture and plate milling

Production roughing and finishing

Heavy steel plate slotting and facing

General precision milling for large parts

Serial 4A3V5A-7

“4A3V” = No. 3 Vertical, High-Speed Dial-Type, Model OM. This code maps to Cincinnati’s No. 3 vertical dial-type mill.

“5A” = order booked in 1953. In Cincinnati’s code, 5A corresponds to 1953 (post-1952 scheme). The digits before the dash give the year code.

“-7” indicates the sequence within that lot (the 7th machine of that booking).

Description:

Key Specifications

• Manufacturer: The Cincinnati Milling Machine Co., Cincinnati, OH, USA

• Model: No. 3 Vertical Milling Machine – Dial-Type

• Serial Number: 4A3V5A-7

• Year Built: 1953

• Electrical: 440V, 3-phase, 60 Hz (110V control)

• Table Size: 62.5" × 15.25" (T-slotted)

• Longitudinal Travel: ~34"

• Cross Travel: ~12"

• Vertical (Knee) Travel: ~20"

• Spindle Taper: NMTB 50

• Spindle Speed Range: ~15 – 1,500 RPM (16-step dial selector)

• Spindle Motor: ~10 HP AC

• Feed Rates: 0.5 – 20 in/min (power feed)

• Rapid Traverse Speeds: Longitudinal ~100 IPM, Cross ~100 IPM, Vertical ~80 IPM

• Weight: ~9,500 – 10,500 lbs

• Floor Space: ~8.5 ft × 9 ft

________________________________________

Functions & Capabilities

• Precision milling of large and heavy work pieces

• All-axis power feeds for consistent, smooth cutting

• Quick spindle speed changes via dial-type selector

• Heavy-duty 50 taper spindle for large-diameter tooling

• Capable of face milling, slotting, drilling, boring, and profiling

• Handles both ferrous and non-ferrous metals

________________________________________

Common Applications

• Machining mold and die bases

• Milling large plates and fixtures

• Slotting and facing heavy steel sections

• Precision boring and profiling of industrial components

• Production runs requiring repeatable accuracy

________________________________________

Used In Industries Like

• Metal fabrication

• Tool and die making

• Heavy equipment manufacturing

• Aerospace and defense

• Energy and power generation

• Shipbuilding

________________________________________

Summary Description

The Cincinnati No. 3 Vertical Milling Machine is a robust, industrial-grade milling solution built for precision and power. With its large table capacity, rigid frame, and quick-change dial-type speed system, it excels in demanding production environments. Its versatility, heavy-duty construction, and 50 taper spindle make it an ideal choice for machining large, high-tolerance parts in a variety of industries.

The Cincinnati No. 3 Vertical is a large-capacity, production-grade milling machine designed for heavy metal removal and precision machining on large workpieces. Its dial-type speed selector allows rapid changes in spindle RPM without belt changes. The robust knee and saddle construction provide high rigidity for both roughing and finishing cuts. This model was widely used in toolrooms, fabrication shops, and manufacturing plants for large part milling, mold bases, and fixture work.